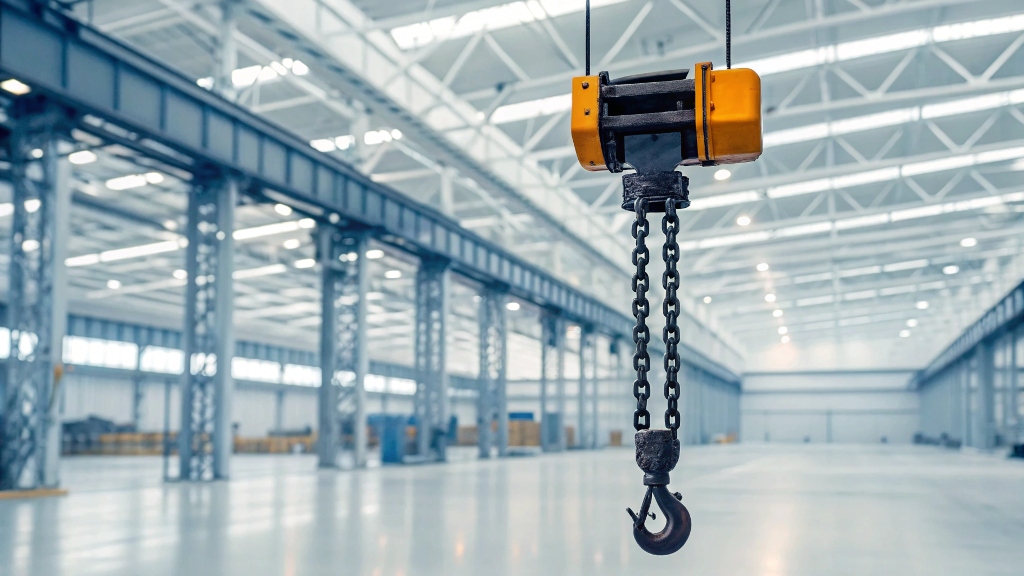

Chain hoists, whether manual or electric, are crucial tools in many industries, providing a reliable way to lift heavy loads. However, like any machinery, regular maintenance is essential to ensure their longevity, safety, and performance. Without proper care, hoists can fail when you need them the most, leading to costly repairs and downtime.

Proper hoist maintenance is key to ensuring both safety and performance. Regular checks on critical components like motors, chains, and safety features will prevent breakdowns and extend the hoist’s lifespan.

How Often Should a Hoist Be Serviced?

The frequency of hoist servicing depends on factors like the type of hoist, usage, environment, and the manufacturer’s recommendations.

- Electric Chain Hoists: Typically require professional servicing at least once a year. In high-usage or harsh environments, more frequent inspections—every six months—may be needed. Regular visual inspections and lubrication are essential.

- Manual Chain Hoists: They need less frequent servicing than electric hoists, but still require professional checks once a year. Daily visual inspections and regular lubrication can keep them in good shape.

Keeping detailed maintenance records ensures timely servicing and helps prevent unexpected issues.

What Does Regular Hoist Maintenance Involve?

The Importance of the Chain

The chain is the most critical part of a hoist, and it must be maintained properly to ensure safe operation. Always use original equipment manufacturer (OEM) chains, as they are made specifically for the hoist’s load. Electric hoist chains are case-hardened, meaning only the outer layer is hardened. When this outer layer wears off, the softer core wears much faster. It’s important for operators to regularly check the chain and ensure it remains in good condition.

Daily Inspections

Routine inspections before each use are vital:

- Visual Check: Look for wear, corrosion, or distortion. Ensure hooks aren’t bent or damaged.

- Functionality Test: Operate the hoist without a load to check for unusual noises or vibrations.

- Control Pendant: Test buttons and switches to ensure they’re functioning properly.

- Load Test: Lift a light load to check smooth operation.

Lubrication and Cleaning

Proper lubrication is essential to reduce friction and avoid chain wear. Lack of lubrication is one of the main causes of chain damage.

- Chain Lubrication: Regularly lubricate with the recommended product to reduce wear and prevent rust.

- Cleaning: Keep the hoist clean and free from debris, especially around the chain.

Periodic Maintenance

Along with daily inspections, periodic servicing is crucial for hoist longevity. Detailed checks should include:

- Electrical Components: Inspect wiring and connections for damage or corrosion.

- Brakes: Check for wear and proper functioning, adjusting or replacing as needed.

- Limit Switches: Test for proper operation, ensuring they prevent over-travel.

Load Testing

Load testing ensures the hoist is capable of safely handling maximum loads:

- Static Load Test: Lift a stationary load to the hoist’s max capacity and hold it to check stability.

- Dynamic Load Test: Lift and lower a load to assess functionality during normal operations.

Regular load testing ensures the hoist can handle tasks safely and effectively, contributing to the overall safety of the operation.