Salt, moisture, and non-stop use ruin ordinary pallet trucks. I’ve seen export operations grind to a halt due to corroded gear.

Stainless steel, galvanized, and powder-coated pallet trucks are best for export because they resist corrosion, withstand heavy use, and stay reliable on docks, ships, and in humid storage areas.

Let’s break down which model fits your dock, your cargo, and your pace—based on real export conditions.

[Table of contents]

- What are the disadvantages of hand pallet trucks?

- What are the three main types of pallet handling trucks?

- How much is a corrosion-resistant pallet jack?

- What is the difference between a pallet truck and a hand truck?

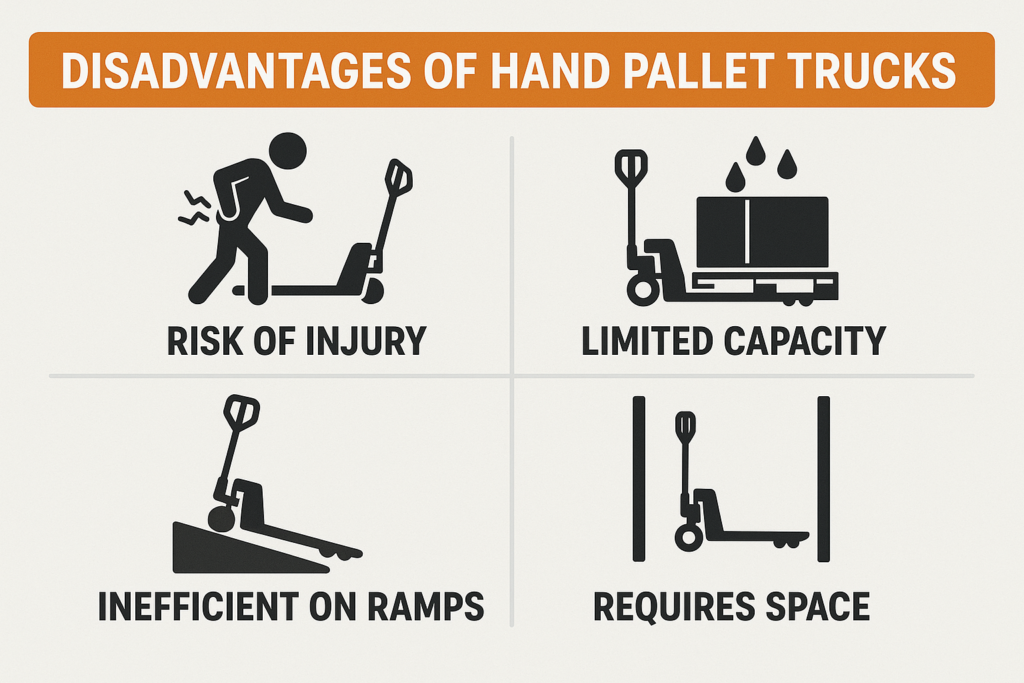

What are the disadvantages of hand pallet trucks?

Manual jacks aren’t perfect—especially at the dock.

They rely on human power, can struggle on slopes, and are vulnerable to rust without the right material coating.

Dive Deeper

Standard steel pallet jacks corrode within weeks near saltwater air. I’ve seen rusted forks bend under load. Manual jacks also depend on operator strength, which can slow down operations when dealing with high-frequency export loading.

Common Issues:

- Hard to use on inclined ramps at container yards

- Require strong operators for consistent use

- Rust quickly in coastal or humid environments

That’s why corrosion-resistant builds—like IVITAL’s stainless and galvanized models—are essential for port logistics.

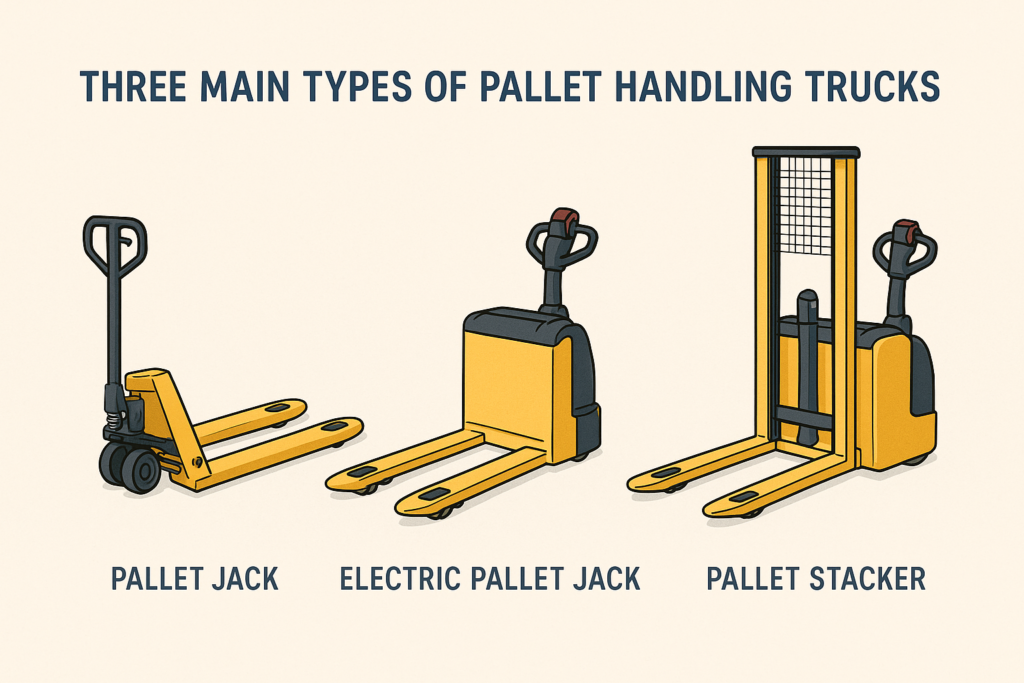

What are the three main types of pallet handling trucks?

Not all trucks are built for the same mission.

Manual, powered, and all-terrain trucks each suit different logistics challenges—from tight warehouses to wet docks.

Dive Deeper

| Type | Best Use | Export Fit? |

|---|---|---|

| Manual | Short-range, flat surfaces | ✅ Yes (if anti-corrosive) |

| Powered | Long distances, frequent cycles | ⚠️ Needs charging zones |

| All-Terrain | Uneven or gravel outdoor conditions | ✅ Good for remote loading |

For most shipping operations, a manual but rugged model is best—no batteries to fail, no electronics to corrode.

IVITAL’s IVT-EX-GZ25 (galvanized) and IVT-SS27 (stainless steel) offer maximum weather resistance with low upkeep.

How much is a corrosion-resistant pallet jack?

Price changes fast—but so does your cost of downtime.

Most corrosion-resistant jacks cost between $400–$900 depending on material, finish, and fork specs.

Dive Deeper

Here’s a quick breakdown:

| Model Type | Avg. Price (USD) | Best For |

|---|---|---|

| Galvanized Steel | $400–$600 | Coastal ports, general cargo |

| Stainless Steel (304) | $600–$900 | Food exports, high humidity |

| Powder-Coated | $350–$500 | Indoor loading near splash zones |

✅ IVITAL offers both cost-effective galvanized options and premium stainless builds for strict hygiene zones or chemical docks.

Both models include:

- Sealed bearings for long-term use

- Grease ports for quick maintenance

- Full ISO 3691-5 compliance

What is the difference between a pallet truck and a hand truck?

A lot of buyers confuse the two. I did too.

Pallet trucks handle full pallet loads with forks; hand trucks are upright tools for boxes or smaller crates.

Dive Deeper

| Feature | Pallet Truck | Hand Truck |

|---|---|---|

| Load Style | Flat, full pallets | Stacked cartons or crates |

| Weight Limit | Up to 5,500 lbs | Usually under 500 lbs |

| Use Location | Warehouse floors, containers | Indoor offices, shops |

If you’re dealing with docks, forklifts, or stacking pallets inside 20-foot containers—you need a corrosion-resistant pallet jack, not a dolly.

Conclusion

Corrosion-resistant pallet jacks are a must for export. Choose one that fits your dock, not just your budget.