Chain strength isn’t just technical—it’s a safety decision that can save lives.

Electric hoist chains are commonly made from G80 alloy steel, which is safe for lifting when certified and properly rated, but G100 offers higher strength for more demanding applications.

I’ve seen factories choose G80 simply because it’s the standard—without asking if it’s the right grade for their lifting intensity. Let’s clear up what you should really be looking for.

[Table of contents]

- What is a G80 chain rating?

- What grade alloy steel chain is used for hoists?

- What is the difference between G80 and G100 chains?

- What chain standards ensure lifting safety?

- How to select the right chain for your electric hoist?

What is a G80 chain rating?

G80 is one of the most common chain grades used in lifting.

G80 chain is made from alloy steel and offers high tensile strength, with a working load limit of 3,500–18,100 lbs depending on diameter.

Dive Deeper

G80 chains must meet standards like:

- ASTM A391 / EN 818-7

- Minimum 20% elongation before fracture

- Toughness and fatigue resistance

They are heat-treated alloy steel, usually quenched and tempered to reach the necessary durability.

What grade alloy steel chain is used for hoists?

Not all chain grades are safe for overhead lifting.

Only G80 and G100 alloy steel chains are approved for electric hoists, with G80 being the industry baseline for safe overhead lifting.

Dive Deeper

| Chain Grade | Suitable for Lifting? | Material Type | Common Use Case |

|---|---|---|---|

| G30 / G43 | ❌ No | Carbon steel | Transport, marine use only |

| G70 | ❌ No | Heat-treated steel | Load securement, not lifting |

| G80 | ✅ Yes | Alloy steel | Hoists, cranes, slings |

| G100 | ✅ Yes | Higher-grade alloy | Heavy-duty hoists and cranes |

Buying chains without grade markings is a red flag. Always check for embossed markings and manufacturer certificates.

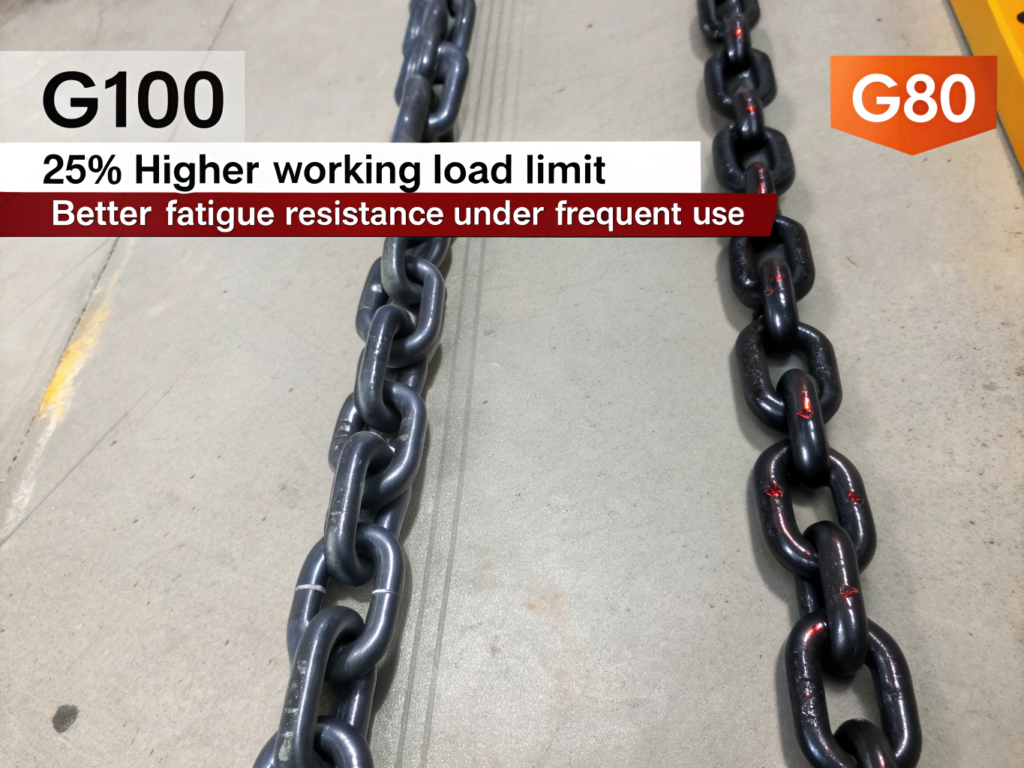

What is the difference between G80 and G100 chains?

G100 is a stronger, newer generation lifting chain.

G100 chain has a ~25% higher working load limit than G80 of the same size and offers better fatigue resistance under frequent use.

Dive Deeper

| Feature | G80 Chain | G100 Chain |

|---|---|---|

| Material | Alloy steel | High-tensile alloy |

| Safety Factor | 4:1 | 4:1 |

| WLL (8mm chain) | ~2,500 kg | ~3,150 kg |

| Common Use Case | Standard hoists | Heavy-duty / frequent lifting |

| Cost | Lower | ~10–15% higher |

G80 is still widely used due to cost and availability, but G100 is recommended for high-frequency or heavy-load operations.

What chain standards ensure lifting safety?

Chains are only safe if they’re manufactured and tested under global safety standards.

Look for compliance with ASTM, EN 818, ISO, and OSHA standards to ensure chain safety for overhead lifting.

Dive Deeper

| Standard | Region | What It Covers |

|---|---|---|

| ASTM A391 | USA | Alloy steel chain manufacturing |

| EN 818-7 | EU | Short-link lifting chain properties |

| ISO 3076 | Global | Chain link and heat-treatment standards |

| OSHA 1910.184 | USA | Hoist sling and lifting chain rules |

Ask your supplier for:

- Load test certificate

- Material traceability

- Embossed grade ID on each chain link

How to select the right chain for your electric hoist?

Start with your lifting needs, not just chain size.

Choose G80 for general lifting; upgrade to G100 if the hoist is used frequently, near max capacity, or in safety-critical environments.

Dive Deeper

| Selection Factor | G80 Chain | G100 Chain |

|---|---|---|

| Standard factory use | ✅ Recommended | ✅ Optional upgrade |

| Near-capacity usage | ⚠ May be limited | ✅ Higher safety margin |

| Outdoor environment | ✅ With coating | ✅ Better fatigue performance |

| Regulatory compliance | ✅ Certified | ✅ Certified |

Don’t just compare price—consider lifespan, fatigue resistance, and usage cycles.

Conclusion

G80 is strong. But safety depends on grade, certification, and the job it’s used for.