Steel wire ropes are used in many industries for lifting and towing heavy loads. It’s important to know the difference between 6×19 and 6×37 wire ropes so you can choose the right one for your needs.

The main difference between 6×19 and 6×37 steel wire ropes is how they’re made. 6×19 has six strands with 16-26 wires per strand. This makes it more resistant to wear and tear and tougher overall. 6×37 has six strands with 27-49 wires per strand. This makes it more flexible and easier to spool. Each type has its own uses in different industries.

Now that we know the basics, let’s look at some specific applications and benefits of each type of wire rope.

What’s the Difference Between 6×19 and 6X37 Wire Rope?

6×19 wire rope has larger outer wires, which makes it more resistant to abrasion and crushing. This makes it good for applications where the rope is going to be in tough conditions or it’s going to get beat up. It usually has 19 wires per strand, which makes it stronger.

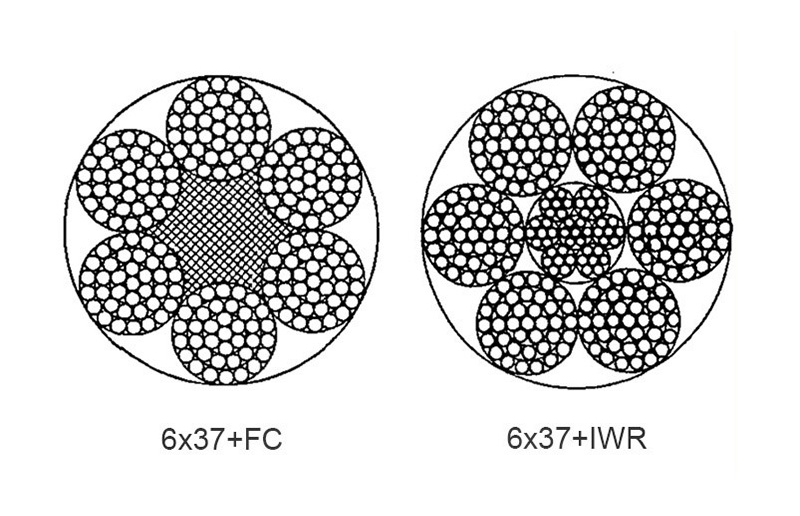

6×37 wire rope has more smaller wires per strand, which makes it more flexible. This makes it good for applications where the rope is going to be bent a lot or spooled a lot, like on cranes and other lifting equipment. The more wires also make it spool smoother and wear less on pulleys and drums.

Parameter Differences

- Construction:

- 6×19: Comprised of six strands with 16 to 26 wires per strand, typically 19 wires. The larger outer wires enhance abrasion and crush resistance.

- 6×37: Also consists of six strands but contains 27 to 49 wires per strand, usually 37 wires. This design allows for improved flexibility.

- Tensile Strength:

- 6×19 typically has higher tensile strength, suitable for heavy load applications.

- 6×37, while slightly lower in tensile strength, excels in flexibility for frequent bending and spooling.

- Weight:

- 6×19 has a higher weight per unit length due to the larger wires.

- 6×37 is relatively lighter per unit length because of its smaller diameter wires.

Weight Examples

- A common diameter for 6×19 steel wire rope (e.g., 10mm) weighs approximately 0.4-0.5 kg/m.

- In contrast, the same diameter for 6×37 steel wire rope may weigh around 0.3-0.4 kg/m.

Load Capacity

6×19 Wire Rope

The working load limits for 6×19 wire rope are generally rated in tons, depending on the diameter:

- 1/4″ diameter: Approximately 0.65 tons vertically, 1.3 tons in a basket configuration, and 0.48 tons in a choker configuration.

- 3/8″ diameter: 1.4 tons (vertical), 2.9 tons (basket).

- 1/2″ diameter: 2.5 tons (vertical), 5.1 tons (basket).

- 3/4″ diameter: 5.6 tons (vertical), 11 tons (basket).

6×37 Wire Rope

The rated capacities for 6×37 wire rope are higher due to its construction:

- 1-1/4″ diameter: Can support about 15 tons vertically and up to 30 tons in a basket hitch.

- 1-1/2″ diameter: 21 tons (vertical), 42 tons (basket).

- 2″ diameter: 37 tons (vertical), 73 tons (basket).

What’s Good About 6×19 Rope Over 6×37?

One big thing about 6×19 is that it’s tough. The bigger wires make it more resistant to abrasion, which makes it a good choice for applications in rough environments, like construction and mining. However, while 6×19 is tough, it doesn’t have as much fatigue resistance as 6×37. That means that if you’re bending it back and forth all the time, 6×19 is going to wear out faster than 6×37.

What’s 6X37 Wire Rope Used For?

6×37 wire rope is used for applications that require a lot of flex, like marine rigging and heavy lifting in industrial settings. It’s designed to bend easily around drums and pulleys, which helps prevent damage during operation. It’s also good for towing applications where you need to make quick moves.

What is 6×19 Wire Rope Used For?

The 6×19 class is used when you need wire rope that can resist abrasion and crushing. It’s often used in construction, heavy equipment, and mining, where the wire rope might rub against rough surfaces and carry heavy loads. It’s built tough to last longer in tough conditions.

Summary

So, when it comes down to it, you have to make the choice between 6×19 and 6×37 wire rope based on what you need. Knowing the differences between the two will help you use them more safely and efficiently in different applications. If you need something that’s tough and can handle abrasion, 6×19 is what you want. If you need something that’s more flexible and can move around more, 6×37 is what you want.