A rigger’s job is to make sure the thing that picks up heavy stuff is safe and secure. Rigging is a skilled trade that requires care, precision, and patience. With knowledge and experience, a rigger uses quality rigging gear to create a mechanical system to pick up heavy stuff using a crane, hoist, or other lifting device. It is important to use quality rigging gear so you can do the job right, do it safely, do it on time, and not have any problems.

Rigging is something that has to be done to Australian Standards, local regulations, and occupational health and safety standards. Riggers are hired on construction and industrial sites to build the system and make sure it works right when you use it. At IVITALRIGGING, we stock a wide range of rigging gear and components that can be used for different rigging jobs. All the gear we stock meets the Australian Standards.

To help you understand more about rigging gear, what you can use it for, and why it’s important to use the right gear, we have put together this guide. If you have any other questions about rigging or rigging gear, give us a call and we can have a confidential chat to point you in the right direction.

What’s a rigger do?

A rigger is a key player on construction and industrial sites. A rigger’s job is to figure out how big and heavy something is, then pick the right stuff to make sure it can be moved safely, securely and efficiently. A rigger puts up and uses cables, ropes, pulleys, winches and other lifting gear to hold the load, let the crane or hoist pick it up and move it somewhere else without it falling apart, coming apart or breaking the lifting gear. As part of the job, a rigger also checks, fixes and takes care of the rigging gear to make sure it works right when you use it.

Why do riggers need rigging gear?

Riggers need rigging gear to move loads from one place to another. On construction and industrial sites, it’s common to move large, heavy loads from different locations at different elevations and in tight spaces. You need special gear that’s made and designed not to twist, bend, distort, or fail when you put a heavy load on it. We stock gear that’s designed and rated for specific rigging applications so that the gear works safely in the tough environment you’re using it in.

How do I choose rigging gear?

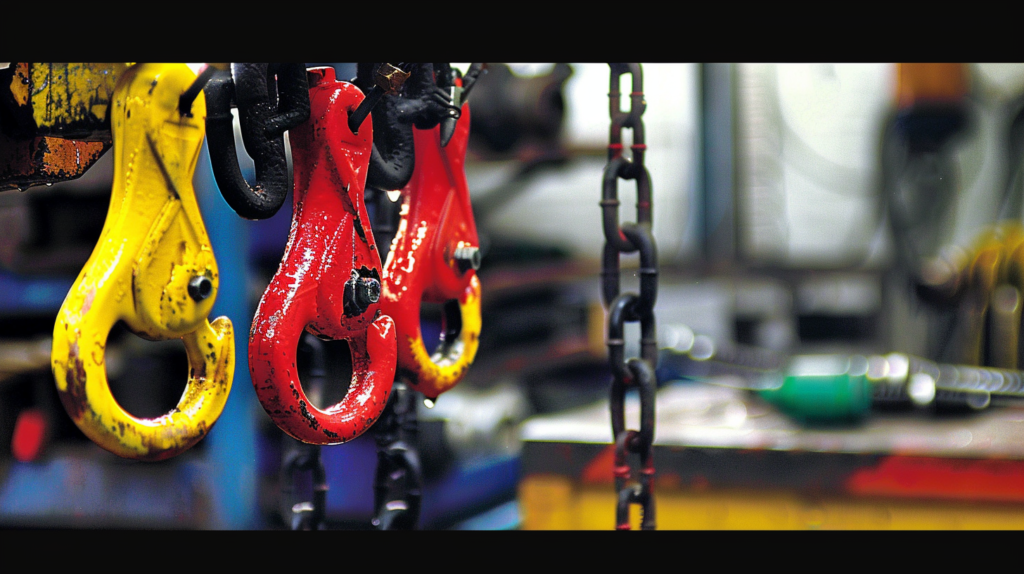

Choosing the right rigging gear is important. Otherwise, you won’t be able to secure and move your load properly. We have a huge range of rigging gear for different uses. We have chain, wire rope, wire rope grips, slings, block and tackle, lever blocks, hoists, hooks, shorteners, top rings, links, turnbuckles, rigging screws, eye bolts eye nuts, d shackles, bow shackles safety shackles thimble eyes and other rigging gear so you can make up a system that suits your needs. We’re happy to talk to you about your specific needs so we can help you choose the right gear to get the job done.

How to maintain rigging gear?

Riggers need to look at, take care of, and fix their rigging gear so it works right. This gear is used in rough places and jobs where the parts can get stressed. When you lift heavy stuff, it can twist, jerk, squeeze, and put other pressures on the parts. This can damage the rigging parts and/or pieces. Riggers need to have a book and a plan to look at their gear. They need to look at the gear, the parts, and the pieces on a regular basis. They need to fix or change the parts and pieces that are worn out or damaged. If they don’t, they can get hurt on the job.

Rigging Gear Q&A

Q: What’s in rigging gear?

A: Rigging gear is the stuff you put together to make a rig. It includes things like turnbuckles, shackles, wire rope, wire rope clips, chain, thimbles, hooks, master links, and a whole lot more.

Q: What kind of stuff is in a rigging kit?

A: Rigging equipment helps you move heavy stuff around a construction or industrial site without hurting yourself. It includes chain falls, come-alongs, come-along clamps, cranes, mechanical hoists, block and tackle, trolleys, slings, pulleys, sheave blocks and a whole lot more.

Q: What’s rigging for?

A: Rigging is for moving heavy loads from one place to another on a construction or industrial site. Rigging is also the process of securing a load or structure with ropes, cable, chains, and other mechanical devices and fittings so that you can lift and move them safely or safety restrain and anchor them.

Q: What is basic rigging and slinging?

A: Rigging and slinging is the process of using ropes, chains and other mechanical devices to secure a load and move it to another destination. This is done by slinging the load and lifting it with a crane, hoist or other lifting device.

Q: How much does rigging equipment cost?

A: The cost of rigging equipment depends on the components you need, the type of parts, the application of the component or device and the quantity of parts acquired and the load involved. It is important to choose the right rigging equipment so that you can safely and securely perform your tasks.