When selecting lifting equipment for port and terminal operations, cost is a critical factor. But what influences the price of G80 lifting chains? Understanding these factors can help you make informed purchasing decisions, ensuring safety and cost-efficiency for your business.

The price of G80 lifting chains is influenced by several key factors. These include the material composition (typically high-grade alloy steel), manufacturing processes (like heat treatment and quenching), supply chain logistics, and certification standards (such as OSHA and ASME). Additional factors include the chain’s size, breaking strength, and safety rating, which directly affect its price. These factors collectively determine the chain’s durability and load-bearing capacity, essential for port operations.

Let’s take a deeper look at the factors that affect G80 lifting chain prices, and how you can choose the right one for your business needs.

What Materials Influence the Price of G80 Lifting Chains?

One of the main things that affects the price of a G80 lifting chain is the material it’s made from. G80 chains are usually made from high-grade alloy steel. They use this kind of steel because it’s strong and tough. Alloy steel is strong and light, so the chain is lighter but still strong enough to lift heavy loads.

But not all alloy steel is the same. The better the steel, the more the chain costs. Chains made from top-quality alloy steel that’s been treated more, like heat-treated and tempered, cost more money. But they work better in tough places, like ports.

How Does the Manufacturing Process Affect Costs?

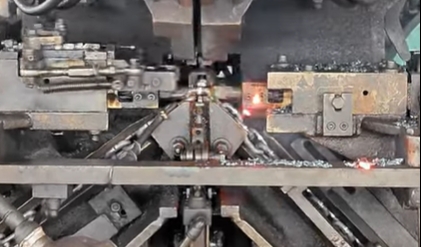

The manufacturing process is a big factor in the cost of G80 lifting chains. These chains go through a number of critical processes like quenching, tempering, and proof testing to make sure they’re strong and durable.

- Quenching and Tempering: These processes make the chain harder and more resistant to wear. Chains that go through a more intense heat treatment process will cost more because it means they meet stricter safety standards.

- Proof Testing: Every G80 chain is proof tested to make sure it can handle a certain load before it’s certified for use. This testing adds to the cost but guarantees the chain will work when you need it in tough applications.

Why Do Chain Specifications Impact Pricing?

G80 chains come in different sizes and specs. They have different diameters and breaking strengths. The bigger and stronger the chain, the more material it takes to make it. The more material it takes to make it, the more it costs. For example, a 3/8″ grade 80 chain with a working load limit of 7,100 lbs will cost more than a 9/32″ chain with a lower working load.

Each chain spec has to meet certain standards. OSHA and ASME set those standards. Those standards also contribute to price differences. Chains with higher working load limits or chains designed for specific applications, like overhead lifting, will be more expensive.

G80 Lifting Chain Pricing Factors

There are several factors that can influence the price of G80 lifting chains. Here are a few examples:

- Raw Material Costs: The price of alloy steel, which is used to make G80 chains, can fluctuate based on global market conditions. When steel prices go up, the cost of manufacturing G80 chains goes up.

- Supply Chain Disruptions: Events like global pandemics or geopolitical tensions can disrupt the supply chain, causing delays and price increases. The longer it takes to get materials or transport goods, the more it costs.

- Market Demand: If there is more demand for lifting chains—maybe because there is a lot of construction or shipping going on—prices will go up because suppliers can’t keep up with demand.

Conclusion

Knowing what affects the price of G80 lifting chains can help you choose the best one for your business. Think about the material, certification, breaking strength, and supplier reputation to make sure you get a safe and cost-effective chain. Talk to experts to make sure you get the right chain for your operation.