A single rigging mistake can cost more than equipment—legal action, fines, and even criminal charges are on the table.

Exceeding the Safe Working Load (SWL) breaches safety regulations such as OSHA 1926 or LOLER 98, exposing companies to fines, civil liability, criminal prosecution, and operational shutdowns.

I once worked with a firm that overloaded a sling by just 20%. The rig failed. No one was hurt—but the investigation resulted in a $120,000 fine and mandatory retraining for all staff. That incident changed how we approach compliance forever.

[Table of Contents]

- What are the legal consequences of exceeding the Safe Working Load?

- Which regulations prohibit lifting beyond rated load limits?

- Can company management be held personally liable for SWL violations?

- What legal precedents exist for overloading-related accidents?

- How can businesses reduce legal risk through lifting compliance?

What are the legal consequences of exceeding the Safe Working Load?

It’s not just about broken equipment—it’s about legal exposure.

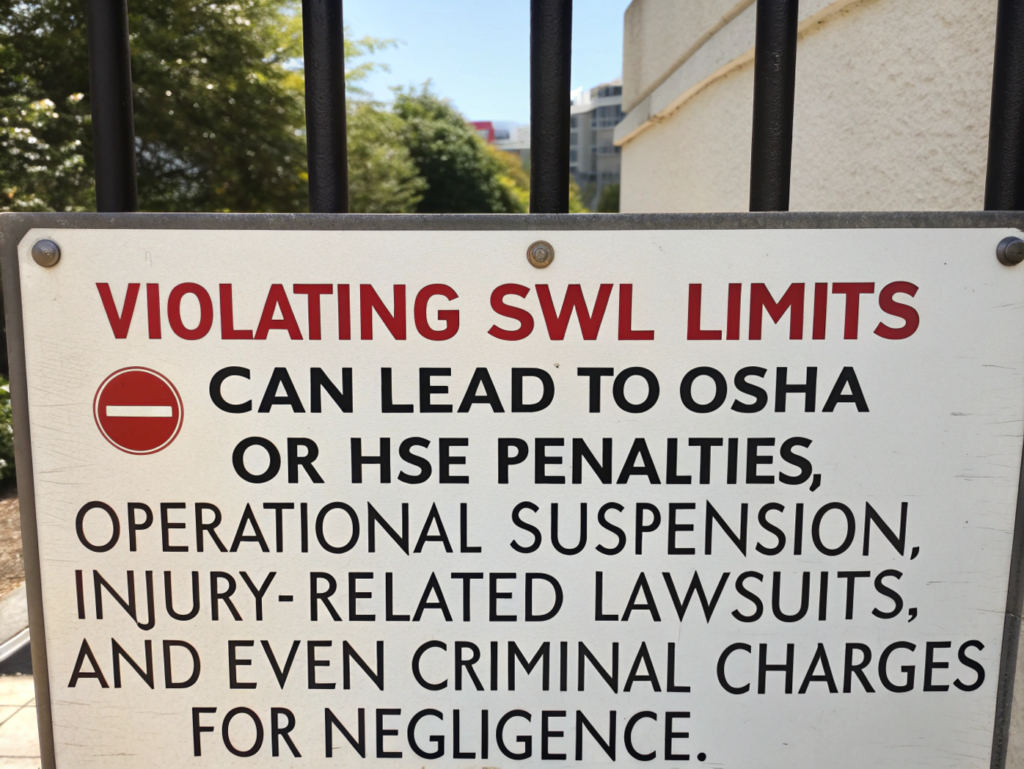

Violating SWL limits can lead to OSHA or HSE penalties, operational suspension, injury-related lawsuits, and even criminal charges for negligence.

DiveDeeper: The cost of a shortcut

According to OSHA 1926.251, lifting equipment must never be used beyond its rated capacity. Violations trigger investigations that often result in:

- Civil lawsuits

- Criminal charges for gross negligence

- Regulatory fines

- Immediate shutdown of the operation until corrective action is taken

The UK’s LOLER 98 similarly enforces criminal penalties for non-compliance, especially if an injury occurs due to overloading.

Which regulations prohibit lifting beyond rated load limits?

Several international and national frameworks address this directly.

OSHA 1926, LOLER 98, and EN 13155 all prohibit lifting gear from being used beyond its SWL/WLL. Compliance is legally enforceable.

DiveDeeper: Core regulations

Here are some of the key lifting safety regulations:

- OSHA 1926.1417 & 1926.251: Covers safe operation and rigging compliance.

- LOLER 98 (UK): Requires all lifting gear to be clearly marked with SWL and used within limits.

- EN 13155 (EU): Sets rigging gear safety requirements, including SWL markings and usage guidelines.

IVITAL products come with full certification to meet these standards, giving your procurement team the documentation needed for legal audits.

Can company management be held personally liable for SWL violations?

Yes—and in many jurisdictions, it’s not just the company that’s at risk.

Supervisors, engineers, and company directors may be held personally liable under workplace safety laws if they allow or ignore SWL violations.

DiveDeeper: When managers are named in lawsuits

Legal experts note that in fatal or serious injury cases, prosecutors may pursue charges against individuals—not just the business entity. Under the UK Corporate Manslaughter Act, and U.S. state-level OSHA laws, executives may face:

- Fines

- Disqualification from management roles

- Imprisonment in extreme cases

What legal precedents exist for overloading-related accidents?

There’s a long trail of legal history tied to lifting failures.

Cases involving overloaded lifting gear often lead to negligence claims, high compensation payouts, and long-term reputational damage.

DiveDeeper: Real-world legal outcomes

- In one U.S. case, a construction firm was fined $180,000 after a hoist failure injured a worker—the lift exceeded the sling’s SWL.

- A UK warehouse manager was found liable for manslaughter after ignoring repeated warnings about overloaded cranes that eventually collapsed.

These cases underscore the need for proactive compliance.

How can businesses reduce legal risk through lifting compliance?

Compliance must be proactive, documented, and enforced from the top.

Implement regular equipment inspections, enforce certified training, and only procure lifting gear with clear SWL documentation and certifications.

DiveDeeper: A legal shield through compliance

IVITAL offers fully certified products, each labeled with a WLL and linked to test certificates. Businesses can reduce liability by:

- Maintaining compliance logs

- Conducting third-party audits

- Mandating lifting gear inspections before every shift

- Procuring only from compliant suppliers

Documented compliance isn’t just good practice—it’s your legal defense if something goes wrong.

Summary

Exceeding SWL doesn’t just break equipment—it can break your business legally. Stay compliant, stay documented, and choose certified products like IVITAL’s to protect your people and your company.