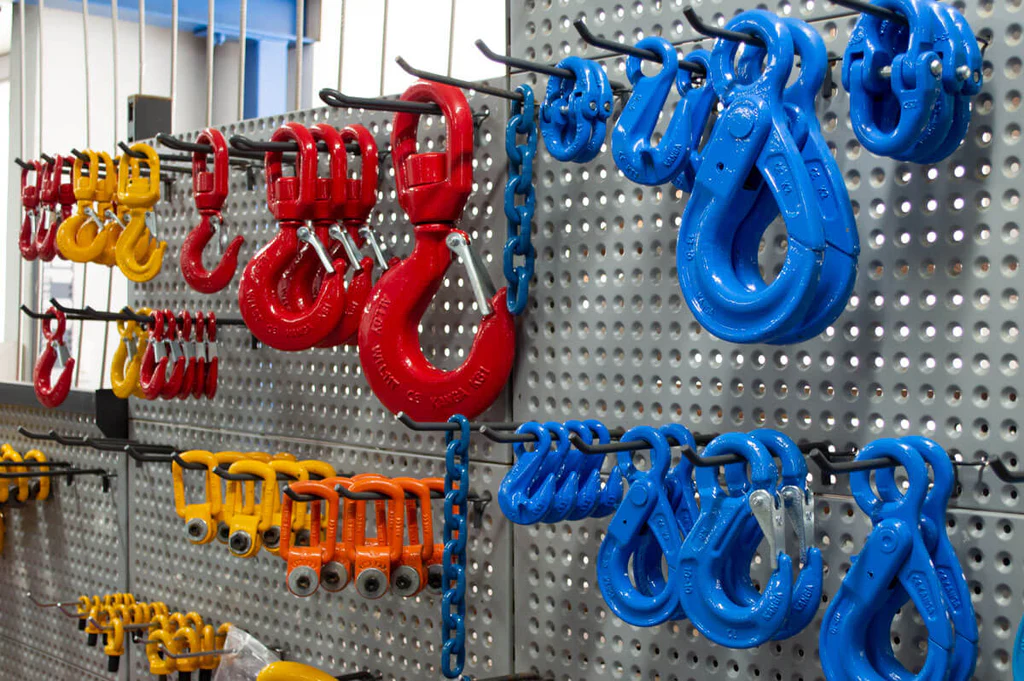

Rigging hooks are used to lift loads, tow things, or do other heavy-duty rigging jobs. They come with different end connectors so you can quickly and easily attach them to different rigging applications. They have different designs, strengths, and capacities.

There are many different types of rigging hooks, such as hoist hooks, slip hooks, grab hooks, clevis hooks, sling hooks, and self-locking hooks, etc., but there are three main ways to attach a lifting hook or sling hook to the sling: eye hooks, clevis hooks, and swivel hooks, but there are more types of rigging hooks if differ in hooks opening design, strength, and capacity.

What are the types of rigging hooks

Eye Hooks

- Eye hooks are the hooks you put the slings on, you can put the hooks anywhere you want and hook them to the load.

Clevis Hooks

- These hooks have a U-shaped thing with a pin or bolt that you can put shackles, chain, or other stuff on to make sure the load is connected.

Swivel Hooks

- There are two types of swivel hooks, swivel hook for positon and swivel hook with bearing. The swivel hook for position is used to position the hook onto the pick point, not designed to load while rotating. Swivel hook with bearing has a bearing on the top and allows the hook to rotate while loading to prevent twisting the lifting slings.

Grab Hooks

- Grab hooks have a special shallow throat opening to keep a chain from slipping off the hook, it is commonly used to load binding, shorten or hold as an end on a transport chain. The throat allows for easy and secure engages the chain between the links for quick and non-slip handling.

Slip Hooks

- Slip hooks have a wider throat than the grab hook, also sometimes called a sling hook due to its wider throat. Most of the time, it has a latch to keep the attached object security.

Hoist Hooks

- Hoist hooks also are known as hoist lifting hook, is designed for attaching to the end of wire rope slings, chain slings, complete with a safety latch, to lift objects quickly by crane and land them securely without using of shackles

Self-locking Hooks

- Self-locking hooks can prevent the hook from being accidentally dislodged when under heavy load.

What are the technical terms for selecting the right rigging?

Grades

Steel comes in different grades. Grade 30, grade 43, and grade 70 are all tensile strengths of steel. Grade 80 and grade 100 are also tensile strengths of steel. Grade 80 and grade 100 are used for overhead lifting. Grade 100 provides approximately 25% higher working load limits than grade 80.

Stuff

We usually sell hooks for lifting stuff in three different materials: carbon steel, alloy steel, and stainless steel. You use carbon steel hooks for stuff like towing, pulling, or tying stuff down, but you can’t use them for lifting stuff over your head. You can use alloy steel hooks for lifting stuff over your head. Stainless steel hooks are better than carbon steel and alloy steel hooks because they don’t rust as much. They’re good for lifting stuff over your head and they’re good for lifting stuff in the ocean.

W.L.L

Sometimes called Safe Working Load, abbreviated W.L.L or SWL. It is the maximum load that should be applied to the item. So, never exceed the Working Load Limit of the hooks or shock load the chain or fittings. Choose the correct W.L.L and proper size chain to fit the throat of the hook, which typically have the load information and dimensions.

MBL

Minimum Breaking Load is the minimum force that lifting hooks were found to break, divided by a safety factor (SF = MBL / WLL) equals the working load limit, usually the carbon steel hoist hooks safety factor is 5:1, while the alloy steel hoist hooks safety factor is 4:1.