Description

| Approx | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| NominalDiameter | Weight | ||||||||

| Constuction | kg/100m | 1570N/mm² | 1770N/mm² | 1960N/mm² | |||||

| mm | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS | |

| 8 | 23.10/22.60 | 25.40 | 30.30 | 32.70 | 32.20 | 36.90 | 37.80 | 40.80 | |

| 12 | 52.00/51.00 | 57.30 | 68.20 | 73.70 | 77.00 | 83.00 | 85.20 | 92.00 | |

| 6*61+FC | 20 | 144/142 | 159 | 190 | 205 | 214 | 231 | 236 | 255 |

| 26 | 244/239 | 269 | 321 | 346 | 361 | 390 | 400 | 432 | |

| 30 | 325/319 | 358 | 427 | 461 | 481 | 519 | 532 | 575 | |

| 36 | 468/459 | 516 | 614 | 663 | 693 | 748 | 767 | 828 | |

| 40 | 578/566 | 637 | 759 | 819 | 855 | 923 | 947 | 1022 | |

| 46 | 764/749 | 842 | 1000 | 1080 | 1130 | 1220 | 1252 | 1352 | |

| 50 | 903/885 | 995 | 1190 | 1280 | 1340 | 1440 | 1479 | 1597 | |

| 6*61+IWR | 56 | 1130/1110 | 1250 | 1490 | 1610 | 1680 | 1810 | 1856 | 2000 |

| 60 | 1300/1270 | 1430 | 1710 | 1840 | 1920 | 2080 | 2130 | 2297 | |

| 66 | 1570/1540 | 1730 | 2070 | 2230 | 2330 | 2510 | 2578 | 2780 | |

| 68 | 1670/1640 | 1840 | 2190 | 2370 | 2470 | 2670 | 2737 | 2950 | |

| 70 | 1770/1730 | 1950 | 2320 | 2510 | 2620 | 2830 | 2900 | 3127 | |

| Approx | |||||||||

| NominalDiameter | Weight | ||||||||

| Constuction | kg/100m | 1570N/mm² | 1770N/mm² | 1960N/mm² | |||||

| mm | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS | |

| 8 | 22.80 | 26.56 | 27.30 | 32.30 | 30.80 | 36.40 | 34.20 | 40.30 | |

| 16 | 91.20 | 106 | 110 | 129 | 123 | 146 | 137 | 161 | |

| 20 | 143 | 166 | 171 | 202 | 193 | 228 | 214 | 252 | |

| 8*61+FC | 26 | 241 | 280 | 289 | 341 | 326 | 384 | 361 | 426 |

| 30 | 321 | 374 | 385 | 454 | 434 | 512 | 480 | 567 | |

| 32 | 365 | 425 | 438 | 516 | 493 | 582 | 546 | 645 | |

| 36 | 462 | 538 | 554 | 654 | 624 | 737 | 691 | 816 | |

| 40 | 570 | 664 | 684 | 807 | 771 | 910 | 853 | 1007 | |

| 46 | 754 | 880.8 | 904 | 1066 | 1020 | 1203 | 1129 | 1331 | |

| 50 | 890 | 1038 | 1068 | 1260 | 1204 | 1420 | 1333 | 1573 | |

| 8*61+IWR | 56 | 1117 | 1302 | 1339 | 1580 | 1510 | 1782 | 1672 | 1974 |

| 60 | 1282 | 1494 | 1538 | 1815 | 1734 | 2046 | 1920 | 2265 | |

| 66 | 1551 | 1808 | 1860 | 2196 | 2098 | 2475 | 2323 | 2741 | |

| 70 | 1745 | 2034 | 2093 | 2470 | 2360 | 2785 | 2613 | 3083 |

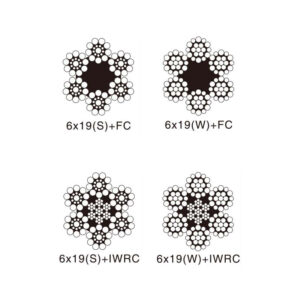

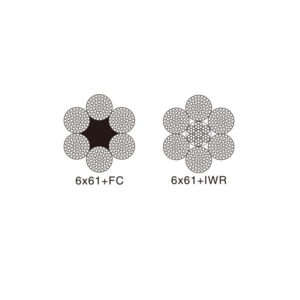

Steel Wire Rope (6×61+FC, 6×61+IWR) is designed for a wide range of industrial applications, offering high strength, flexibility, and durability. Available in both ungalvanized and galvanized options, this wire rope meets the rigorous demands of lifting, rigging, and hoisting operations.

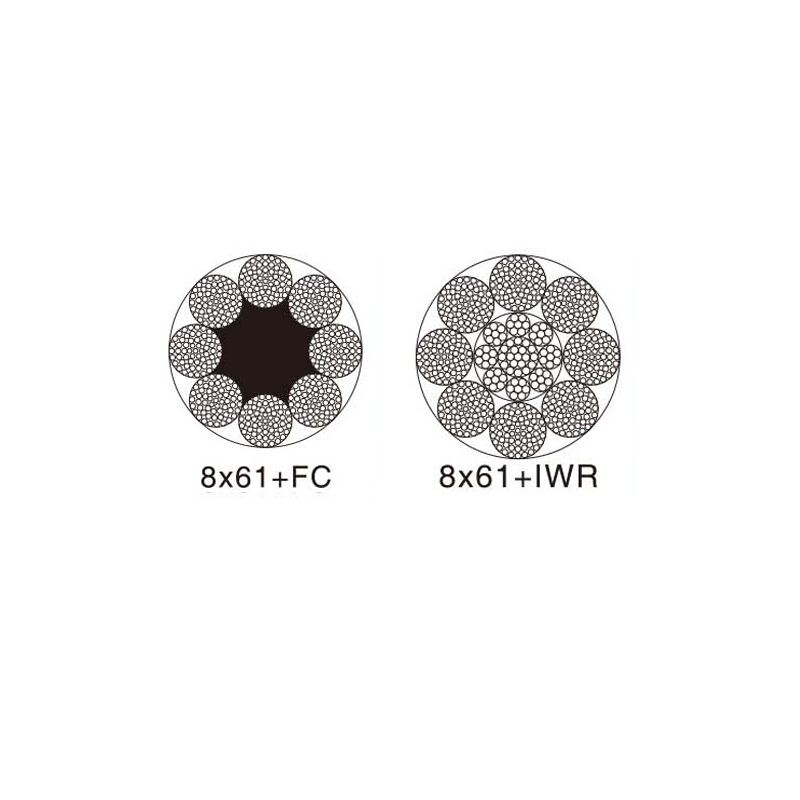

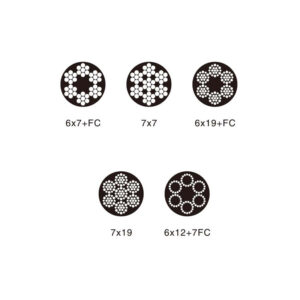

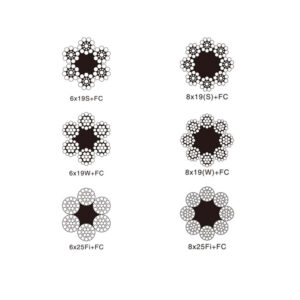

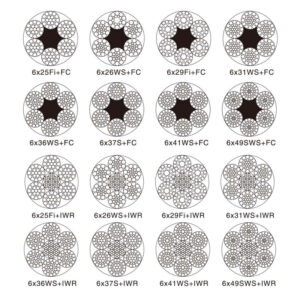

The 6×61 construction features six strands of 61 wires each, providing excellent flexibility and resistance to fatigue. The fiber core (FC) option offers enhanced flexibility and shock absorption, making it ideal for general-purpose applications. In contrast, the independent wire rope core (IWR) version provides additional strength and resistance to crushing, making it suitable for more demanding tasks.

Galvanized wire ropes are coated with a layer of zinc, providing superior corrosion resistance, which is essential for outdoor and marine environments. Ungalvanized wire ropes, while not corrosion-resistant, offer higher tensile strength and are commonly used in controlled environments where exposure to the elements is minimal.

These steel wire ropes are manufactured to high-quality standards, ensuring reliable performance and safety in critical operations. Whether used in construction, shipping, or mining, the 6×61+FC and 6×61+IWR wire ropes deliver consistent and dependable results.

• Available in both ungalvanized and galvanized finishes for various environmental conditions.

• 6×61 construction ensures excellent flexibility and fatigue resistance.

• Fiber core (FC) option provides superior flexibility, while independent wire rope core (IWR) offers added strength.

• Galvanized ropes feature enhanced corrosion resistance for use in harsh environments.

• Suitable for lifting, rigging, and hoisting applications in industrial settings.