Description

| Appro | Appro | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal | Woight | Nominal Tensile Strengt | Nomina | Woight | Nominal Tensile Strengt | |||||

| Diamate | Minium Breaking Strength (kN) | Diamete | Minium Breaking Strength (kN) | |||||||

| Construction | kg/100m | Construction | kg/100m | |||||||

| mm | NF/SF | 1570N/mm² | 1770N/mm² | mm | NF/SF | 1570N/mm² | 1770N/mm² | |||

| 5 | 6.28/5.78 | 8.20 | 9.25 | 5 | 7.95/7.60 | 11.00 | 12.40 | |||

| 6 | 9.04/8.32 | 11.80 | 13.30 | 8 | 20.40/19.50 | 28.10 | 31.70 | |||

| 7 | 12.30/11.30 | 16.10 | 18.10 | 9 | 25.80/24.60 | 35.60 | 40.10 | |||

| B | 16.10/14.80 | 21.00 | 23.70 | 10 | 31.80/30.40 | 44.00 | 49.60 | |||

| 9 | 20.30/18.70 | 26.60 | 30.00 | 11 | 38.50/36.80 | 53.20 | 60.00 | |||

| 10 | 25.10/23.10 | 32.80 | 37.00 | 12 | 45.80/43.80 | 63.30 | 71.40 | |||

| 11 | 30.40/28.00 | 39.70 | 44.80 | 13 | 53.70/51.40 | 74.30 | 83.80 | |||

| 12 | 36.10/33.30 | 47.30 | 53.30 | 14 | 62.30/59.60 | 86.20 | 97.10 | |||

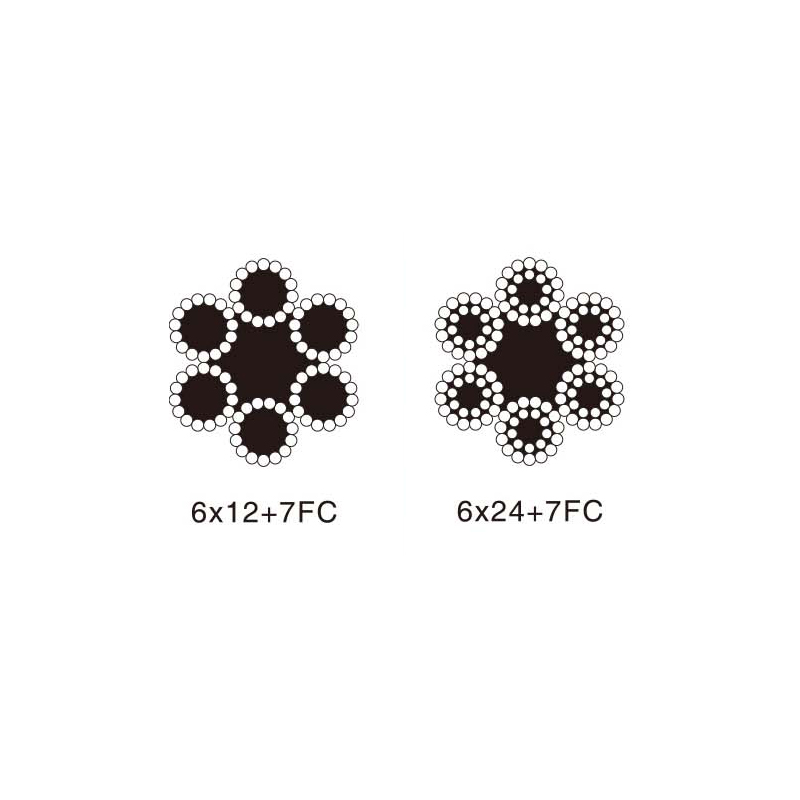

| 6*12+7FC | 14 | 49.20/45.30 | 64.30 | 72.50 | 16 | 81.40/77.80 | 113.00 | 127,00 | ||

| 16 | 64.30/59.10 | 84.00 | 94.70 | 18 | 103.00/98.50 | 142.00 | 161.00 | |||

| 18 | 81.30/74.80 | 106.00 | 120.00 | 20 | 127/122 | 176.00 | 198.00 | |||

| 20 | 100/92.40 | 131.00 | 148.00 | 22 | 154/147 | 213.00 | 240.00 | |||

| 22 | 121/112 | 159.00 | 179.00 | 6*24+7FC | 24 | 183/175 | 253.00 | 285.00 | ||

| 24 | 145/133 | 189.00 | 213.00 | 26 | 215/206 | 297.00 | 335.00 | |||

| 26 | 170/156 | 222.00 | 250.00 | 28 | 249/238 | 345.00 | 389.00 | |||

| 28 | 197/181 | 257.00 | 290.00 | 30 | 286/274 | 396.00 | 446.00 | |||

| 30 | 226/208 | 295.00 | 333.00 | 32 | 326/311 | 450.00 | 507.00 | |||

| 32 | 257/237 | 336.00 | 379.00 | 34 | 368/351 | 508.00 | 573.00 | |||

| 34 | 290/267 | 379.00 | 428.00 | 36 | 412/394 | 570.00 | 642.00 | |||

| 36 | 325/299 | 425.00 | 479.00 | 38 | 459/439 | 635.00 | 716.00 | |||

| 38 | 362/334 | 474.00 | 534.00 | 40 | 509/486 | 703.00 | 793.00 | |||

| 40 | 402/370 | 525.00 | 592.00 | 42 | 561/536 | 775.00 | 874.00 | |||

| 42 | 442/407 | 579.00 | 652.00 | 44 | 616/589 | 851.00 | 959.00 | |||

| 44 | 486/447 | 635.00 | 716.00 | 46 | 673/643 | 930.00 | 1050.00 | |||

| 46 | 531/488 | 694.00 | 782.00 | 48 | 733/700 | 1010.00 | 1140.00 | |||

| 50 | 795/760 | 1100.00 | 1240.00 |

Steel Wire Ropes are essential components in heavy-duty lifting, pulling, and securing applications. Available in both ungalvanized and galvanized options, these ropes offer versatility and strength to meet diverse industrial needs.

Ungalvanized steel wire ropes are known for their superior tensile strength and flexibility, making them suitable for environments where exposure to corrosion is minimal. They are commonly used in construction, mining, and heavy machinery operations where raw strength and performance are critical.

Galvanized steel wire ropes, on the other hand, feature a protective zinc coating that enhances their resistance to rust and corrosion, making them ideal for outdoor or marine applications. This zinc coating not only extends the rope’s lifespan but also ensures reliability in harsh conditions, such as in the shipping, marine, and oil industries.

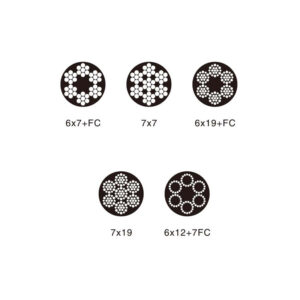

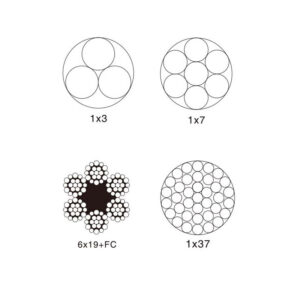

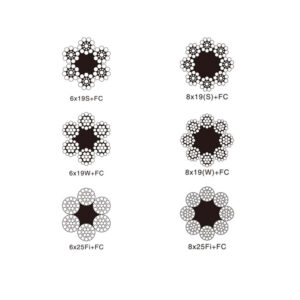

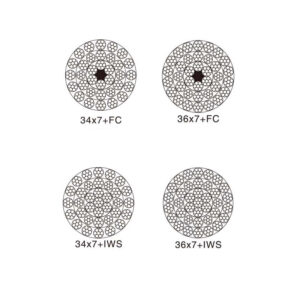

Both variants of our steel wire ropes are constructed with high-grade steel and are available in various configurations, including different diameters and strand patterns. This allows for customized solutions tailored to specific load requirements and operational conditions.

Whether you need ungalvanized ropes for high-stress environments or galvanized ropes for protection against the elements, our steel wire ropes provide the strength, durability, and reliability necessary for your industrial applications.

• Manufactured from high-grade steel, available in ungalvanized and galvanized options.

• Ungalvanized ropes offer superior tensile strength for high-stress applications.

• Galvanized ropes provide enhanced corrosion resistance for outdoor and marine environments.

• Available in various diameters and strand configurations to meet specific needs.

• Suitable for use in construction, mining, marine, and industrial operations.