Description

| Nominal | Approx | Nominal Tensile Strengt | |||||||

|---|---|---|---|---|---|---|---|---|---|

| hana | Weight | Minium Breaking Strength (kN) | |||||||

| Construction | kg/100m | 1570N/mm² | 1770N/mm² | 1960N/mm² | |||||

| mm | FC | IWR/WS | FC | IWR/WS | FC | IWRWS | FC | WA/WS | |

| 1.2 | 0.505 | 0.557 | 0.75 | 0.81 | 0.84 | 0.91 | 0.94 | 1.00 | |

| 2 | 1.40 | 1.55 | 2.08 | 2.25 | 2.35 | 2.54 | 2.60 | 2.81 | |

| 3 | 3.16 | 3.48 | 4.69 | 5.07 | 5.28 | 5.71 | 5.85 | 6.33 | |

| 4 | 5.62 | 6.19 | 8.33 | 9.01 | 9.40 | 10.10 | 10.40 | 11.20 | |

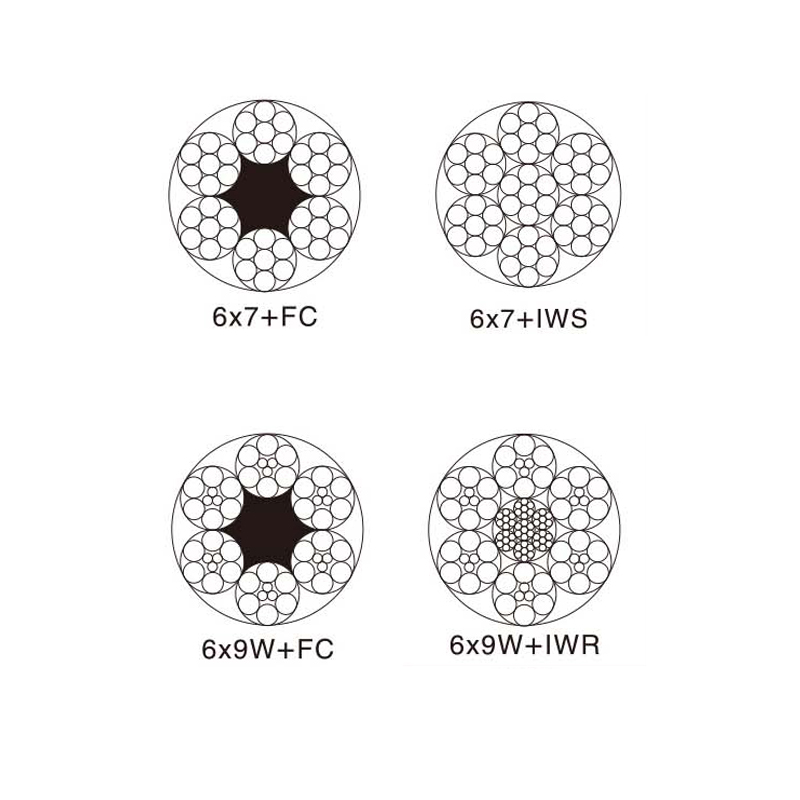

| 6*7+fc | 5 | 8.77 | 9.68 | 13.00 | 14.00 | 14.60 | 15.80 | 16.20 | 17.60 |

| 6 | 12.60 | 13.90 | 18.70 | 20.20 | 21.10 | 22.80 | 23.40 | 25.30 | |

| 7 | 17.20 | 19.00 | 25.50 | 27.60 | 28.70 | 31.10 | 31.80 | 34.40 | |

| 8 | 22.50 | 24.80 | 33.30 | 36.00 | 37.60 | 40.60 | 41.60 | 45.00 | |

| 9 | 20.40 | 31.30 | 42.20 | 45.60 | 47.50 | 51.40 | 52.70 | 56.90 | |

| 10 | 35.10 | 38.70 | 52.10 | 56.30 | 58.70 | 63.50 | 65.00 | 70.30 | |

| 11 | 42.50 | 46.80 | 63.00 | 68.10 | 71.10 | 76.80 | 78.70 | 85.10 | |

| 12 | 50.50 | 55.70 | 75.00 | 81.10 | 84.60 | 91.50 | 93.70 | 101.00 | |

| 6*7+IWS | 13 | 59.30 | 65.40 | 88.00 | 95.20 | 99.30 | 107.00 | 110.00 | 118.00 |

| 14 | 68.80 | 75.90 | 102.00 | 110.00 | 115.00 | 124.00 | 127.00 | 138.00 | |

| 16 | 89.90 | 99.10 | 133.00 | 144.00 | 150.00 | 162.00 | 166.00 | 180.00 | |

| 18 | 114.00 | 125.00 | 168.00 | 182.00 | 190.00 | 205.00 | 210.00 | 228.00 | |

| 20 | 140.00 | 155.00 | 208.00 | 225.00 | 235.00 | 254.00 | 260.00 | 281.00 | |

| 22 | 170.00 | 187.00 | 252.00 | 272.00 | 284.00 | 307.00 | 315.00 | 340.00 | |

| 24 | 202.00 | 223.00 | 300.00 | 324.00 | 338.00 | 366.00 | 374.00 | 405.00 | |

| 6*9W+FC | 26 | 237.00 | 262.00 | 352.00 | 381.00 | 397.00 | 429.00 | 440.00 | 475.00 |

| 28 | 275.00 | 303.00 | 400.00 | 441.00 | 460.00 | 490.00 | 510.00 | 551.00 | |

| 30 | 316.00 | 348.00 | 469.00 | 507.00 | 528.00 | 571.00 | 585.00 | 633.00 | |

| 32 | 359.00 | 396.00 | 533.00 | 577.00 | 601.00 | 650.00 | 666.00 | 720.00 | |

| 34 | 406.00 | 447.00 | 602.00 | 651.00 | 679.00 | 734.00 | 752.00 | 813.00 | |

| 6*9W+IWR | 36 | 455.00 | 502.00 | 675.00 | 730.00 | 761.00 | 823.00 | 843.00 | 912.00 |

| 38 | 507.00 | 559.00 | 752.00 | 813.00 | 848.00 | 917.00 | 940.00 | 1016.00 | |

| 40 | 561.00 | 619.00 | 833.00 | 901.00 | 940.00 | 1016.00 | 1041.00 | 1125.00 | |

| 42 | 619.00 | 682.00 | 919.00 | 994.00 | 1036.00 | 1120.00 | 1147.00 | 1241.00 | |

| 44 | 679.00 | 749.00 | 1009.00 | 1091.00 | 1137.00 | 1230.00 | 1260.00 | 1362.00 | |

| 46 | 742.00 | 818.00 | 1102.00 | 1192.00 | 1243.00 | 1344.00 | 1377.00 | 1488.00 | |

| 48 | 808.00 | 891.00 | 1200.00 | 1298.00 | 1354.00 | 1464.00 | 1499.00 | 1621.00 |

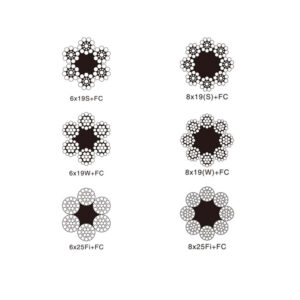

Steel wire ropes, available in both ungalvanized and galvanized finishes, are engineered for demanding industrial applications, offering superior tensile strength and durability. These ropes are constructed from high-quality steel wires, twisted together to form a robust and flexible rope capable of withstanding substantial loads and harsh working conditions.

Ungalvanized steel wire ropes are ideal for applications where corrosion is not a primary concern, providing cost-effective solutions for heavy lifting, construction, and mining operations. Their untreated surface ensures maximum strength and flexibility, making them suitable for environments where the rope’s durability is prioritized over corrosion resistance.

Galvanized steel wire ropes, on the other hand, are coated with a protective layer of zinc, providing excellent corrosion resistance. This makes them ideal for use in marine, outdoor, and other environments where the rope is exposed to moisture and other corrosive elements. The galvanized coating enhances the rope’s longevity and reduces maintenance needs, making it a preferred choice for industries such as shipping, construction, and oil and gas.

Both ungalvanized and galvanized steel wire ropes are available in various sizes and configurations, ensuring they can meet the specific requirements of different industrial applications. These ropes are designed to provide reliable performance, ensuring safety and efficiency in critical operations.

• Available in ungalvanized and galvanized finishes to suit various industrial needs.

• High tensile strength and durability for heavy-duty applications.

• Ungalvanized ropes offer maximum strength and flexibility.

• Galvanized ropes provide excellent corrosion resistance for harsh environments.

• Suitable for lifting, towing, anchoring, and other industrial applications.