Description

| Nominal | Approx | Minimum Breaking Strength(kN) | ||||||

|---|---|---|---|---|---|---|---|---|

| Dlamote | Weight | Double Strength(Mpa) | Sngle Strength (Mpa) | |||||

| mm | kg/100m | 1180/1770 | 1320/1620 | 1370/1770 | 1570/1770 | 1570 | 1620 | 1770 |

| 6 | 12.9 | 16.3 | 16.8 | 17.8 | 19.5 | 18.7 | 19.2 | 21.0 |

| 6.3 | 14.2 | 17.9 | 21.5 | 21.2 | 23.2 | |||

| 6.5 | 15.2 | 19.1 | 19.7 | 20.9 | 22.9 | 21.9 | 22.6 | 24.7 |

| 8 | 23.0 | 28.9 | 29.8 | 31.7 | 34.6 | 33.2 | 34.2 | 37.4 |

| 9 | 29.1 | 36.6 | 37.7 | 40.1 | 43.8 | 42.0 | 43.3 | 47.3 |

| 9.5 | 32.4 | 40.8 | 42.0 | 44.7 | 48.8 | 46.8 | 48.2 | 52.7 |

| 10 | 35.9 | 45.2 | 46.5 | 49.5 | 54.1 | 51.8 | 53.5 | 58.4 |

| 11 | 43.4 | 54.7 | 54.3 | 59.9 | 65.5 | 62.7 | 64.7 | 70.7 |

| 12 | 51.7 | 65.1 | 62.0 | 71.3 | 77.9 | 74.6 | 77.0 | 84.1 |

| 12.7 | 57.9 | 72.9 | 75.0 | 79.8 | 87.3 | 83.6 | 86.2 | 94.2 |

| 13 | 60.7 | 76.4 | 78.6 | 83.7 | 91.5 | 87.6 | 90.3 | 98.7 |

| 14 | 70.4 | 88.6 | 91.2 | 97.0 | 106 | 102 | 105 | 114 |

| 14.3 | 73.4 | 92.4 | 111 | 119 | ||||

| 15 | 80.8 | 102 | - | 111 | 122 | 117 | 131 | |

| 16 | 91.9 | 116 | 119 | 127 | 139 | 133 | 137 | 150 |

| 17.5 | 110 | 138 | 166 | 179 | ||||

| 18 | 116 | 146 | 151 | 160 | 175 | 168 | 173 | 189 |

| 19 | 130 | 163 | 168 | 179 | 195 | 187 | 193 | 211 |

| 20 | 144 | 181 | 186 | 198 | 216 | 207 | 214 | 234 |

| 20.6 | 152 | 192 | 230 | 248 | ||||

| 22 | 174 | 219 | 225 | 240 | 262 | 251 | 259 | 283 |

| 8 | 21.8 | 25.7 | 26.5 | 28.1 | 30.8 | 29. | 30.4 | 33.2 |

| 9 | 27.5 | 32.5 | 35.6 | 38.9 | 37.3 | 42 | ||

| 9.5 | 30.7 | 36.2 | 37.3 | 39.7 | 43.6 | 41.5 | 42.8 | 46.8 |

| 10 | 34.0 | 40.1 | 41.3 | 44.0 | 48.1 | 46.0 | 47.5 | 51.9 |

| 11 | 41.1 | 48.6 | 50.0 | 53.2 | 58.1 | 55.7 | 57.4 | 62.8 |

| 12 | 49.0 | 57.8 | 59.5 | 63.3 | 69.2 | 66.2 | 68.4 | 74.7 |

| 12.7 | 54.8 | 64.7 | 66.6 | 70.9 | 77.5 | 74.2 | 76.6 | 83.6 |

| 13 | 57.5 | 67.8 | 69.8 | 74.3 | 81.2 | 77.7 | 80.2 | 87.6 |

| 14 | 66.6 | 78.7 | 81.0 | 86.1 | 94.2 | 90.2 | 93.0 | 102 |

| 14.3 | 69.5 | 82.1 | 98.9 | 98.3 | 104 | |||

| 15 | 76.5 | 90.3 | 106 | 113 | 108 | 118 | 117 | |

| 16 | 87.0 | 103 | 134 | 123 | 122 | 133 | ||

| 17.5 | 104 | 123 | 149 | 142 | 147 | 149 | ||

| 18 | 110 | 130 | 165 | 159 | 156 | 166 | 154 | 168 |

| 19 | 123 | 145 | 176 | 173 | 184 | 171 | 187 | |

| 20 | 136 | 161 | 200 | 213 | 192 | 190 | 207 | |

| 20.6 | 144 | 170 | 204 | 223 | ||||

| 22 | 165 | 194 | 233 | 230 | 251 |

| Nominal | Approx | Minimum Breaking Strength(kN) | ||||

|---|---|---|---|---|---|---|

| Diamete | Weight | Double Strength(Mpa) | Single Strength(Mpa | |||

| mm | kg/100m | 1180/1770 | 1370/1770 | 1570/1770 | 1570 | 1770 |

| 8 | 26.0 | 33.6 | 35.8 | 38.0 | 35.8 | 40.3 |

| 9 | 33.0 | 42.5 | 45.3 | 48.2 | 45.3 | 51.0 |

| 9.5 | 36.7 | 47.4 | 50.4 | 53.7 | 50.4 | 56.9 |

| 10 | 40.7 | 52.5 | 55.9 | 59.5 | 55.9 | 63.0 |

| 11 | 49.2 | 63.5 | 67.6 | 79.1 | 67.6 | 76.2 |

| 12 | 58.6 | 75.6 | 80.5 | 85.6 | 80.5 | 90.7 |

| 12.7 | 65.6 | 84.7 | 90.1 | 95.9 | 90.1 | 102 |

| 13 | 68.8 | 88.7 | 94.5 | 100 | 94.5 | 105 |

| 14 | 79.8 | 102 | 110 | 117 | 110 | 124 |

| 15 | 91.6 | 118 | 126 | 134 | 126 | 142 |

| 16 | 104 | 134 | 143 | 152 | 143 | 161 |

| 18 | 132 | 170 | 181 | 193 | 181 | 201 |

| 19 | 147 | 190 | 202 | 216 | 202 | 227 |

| 20 | 163 | 210 | 224 | 238 | 224 | 252 |

| 22 | 197 | 254 | 271 | 288 | 271 | 305 |

| Nominal | Approx | Categon | |||

|---|---|---|---|---|---|

| Diameter | Weight | Minimum Breaking Strength(kN | |||

| mm | kg/100m | 1570Mpa | 1770Mpa | 1960Mpa | |

| 24 | 211 | 298 | 336 | 373 | |

| 25 | 229 | 324 | 365 | 404 | |

| 26 | 248 | 350 | 395 | 437 | |

| 27 | 268 | 378 | 426 | 472 | |

| 28 | 288 | 406 | 458 | 507 | |

| 29 | 309 | 436 | 491 | 544 | |

| 30 | 330 | 6x36 | 466 | 526 | 582 |

| 31 | 353 | 498 | 561 | 622 | |

| 32 | 376 | 531 | 598 | 662 | |

| 33 | 400 | 564 | 636 | 704 | |

| 34 | 424 | 599 | 675 | 748 | |

| 35 | 450 | 635 | 716 | 792 | |

| 36 | 476 | 671 | 757 | 838 | |

| 37 | 502 | 709 | 800 | 885 | |

| 38 | 530 | 748 | 843 | 934 |

Steel wire ropes for elevator lifts are engineered to meet the stringent demands of vertical transportation, providing exceptional strength, durability, and flexibility. Manufactured according to GB8903-2005 standards, these ropes are essential components in modern elevators, ensuring smooth and safe operation.

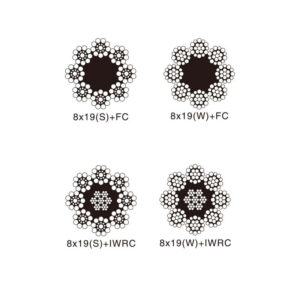

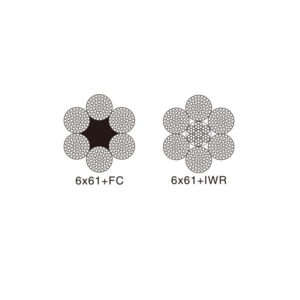

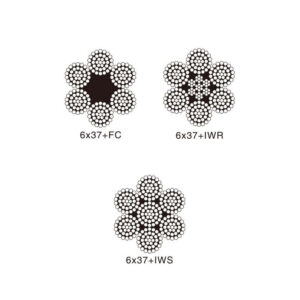

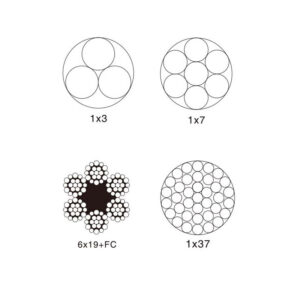

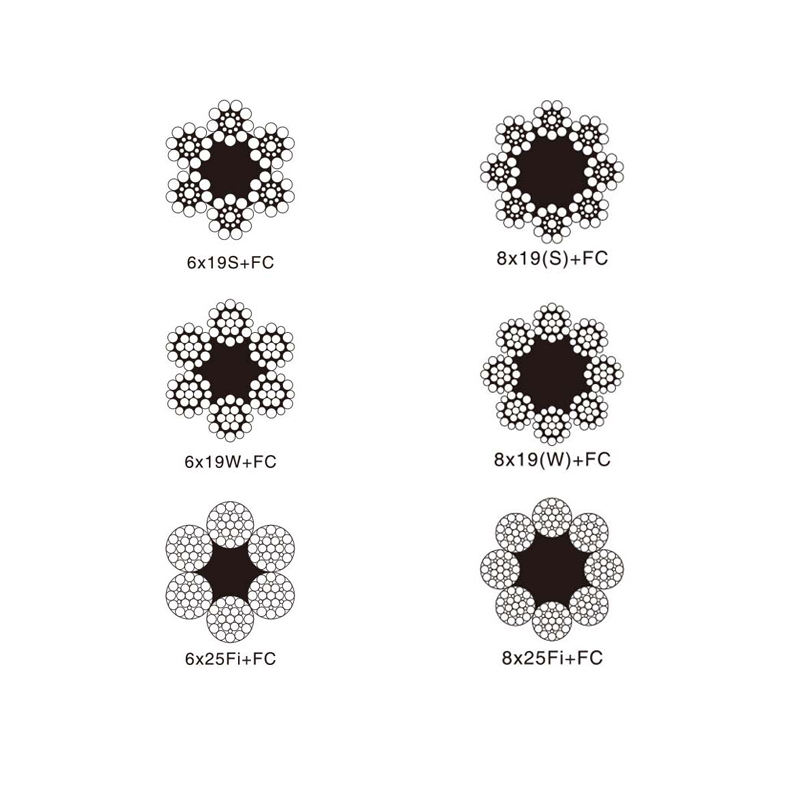

The ropes are available in various constructions, including 6x19S+FC, 6x19W+FC, and 8×19+FC, tailored to different elevator applications. Each construction offers a unique combination of breaking strength and flexibility, making them suitable for various load requirements and elevator speeds. The ropes are made from high-grade steel, providing excellent tensile strength and resistance to wear, even under continuous use.

With a focus on safety, these steel wire ropes undergo rigorous testing to ensure they meet or exceed industry standards. The wires are also available with a galvanized finish to enhance corrosion resistance, further extending the lifespan of the ropes in demanding environments. These features make them a reliable choice for elevator manufacturers and maintenance companies worldwide.

• Conforms to GB8903-2005 standards.

• Available in multiple constructions to suit different elevator systems.

• High tensile strength and wear resistance ensure longevity.

• Optional galvanized finish for enhanced corrosion protection.

• Suitable for both residential and commercial elevator applications.