Description

| Diamole | Unit Weight | MBS(kN) | ||

|---|---|---|---|---|

| Construction | ||||

| (mm) | (kg/100m) | 1770N/mm² | 1960N/mm² | |

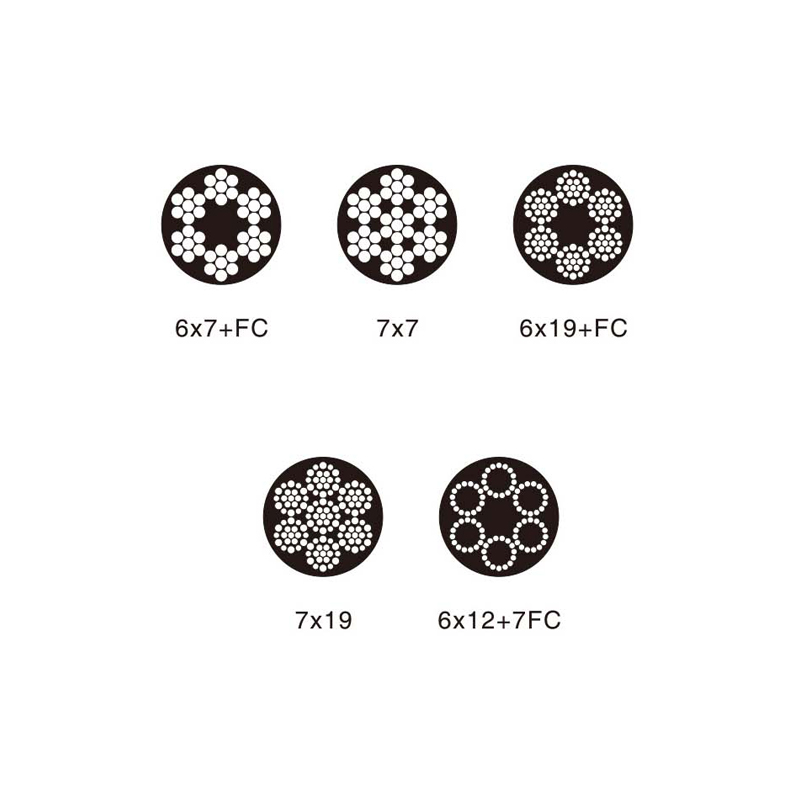

| 6x7+FC PVC/PP/PE | 1.5-2.5 | 1.27 | 1.32 | 1.46 |

| 2.0-3.0 | 2.00 | 2.35 | 2.6 | |

| 3.0-4.0 | 4.02 | 5.29 | 5.86 | |

| 3.0-5.0 | 5.04 | 5.29 | 5.86 | |

| 4.0-5.0 | 6.74 | 9.41 | 10.4 | |

| 4.0-6.0 | 8.00 | 9.41 | 10.4 | |

| 5.0-6.0 | 10.18 | 14.7 | 16.3 | |

| 6.0-8.0 | 16.04 | 21.1 | 23.4 | |

| 8.0-10 | 26.95 | 37.6 | 41.6 | |

| 7x7 pyC/PP/PE | 1.5-2.5 | 1.35 | 1.43 | 1.58 |

| 2.0-3.0 | 2.14 | 2.54 | 2.81 | |

| 3.0-4.0 | 4.34 | 5.71 | 6.32 | |

| 3.0-5.0 | 5.36 | 5.71 | 6.32 | |

| 4.0-5.0 | 7.31 | 10.20 | 11.30 | |

| 4.0-6.0 | 8.56 | 10.20 | 11.30 | |

| 5.0-6.0 | 11.08 | 15.90 | 17.60 | |

| 6.0-8.0 | 17.34 | 22.90 | 25.40 | |

| 8.0-10 | 29.25 | 40.60 | 45.00 | |

| 6x19+FC PVC/PP/PE | 3.0-4.0 | 3.91 | 4.90 | 5.43 |

| 3.0-5.0 | 4.93 | 4.90 | 5.43 | |

| 4.0-5.0 | 6.56 | 8.70 | 9.63 | |

| 4.0-6.0 | 7.82 | 8.70 | 9.63 | |

| 5.0-6.0 | 9.90 | 13.60 | 15.10 | |

| 6.0-8.0 | 15.64 | 19.60 | 21.70 | |

| 8.0-10 | 26.24 | 34.80 | 38.50 | |

| 10-12 | 39.60 | 54.40 | 60.20 | |

| 12-14 | 55.74 | 78.30 | 86.70 | |

| 7x19 PVC/PP/PE | 3.0-4.0 | 4.23 | 5.29 | 5.86 |

| 3.0-5.0 | 5.25 | 5.29 | 5.86 | |

| 4.0-5.0 | 7.12 | 9.40 | 10.40 | |

| 4.0-6.0 | 8.38 | 9.40 | 10.40 | |

| 5.0-6.0 | 10.78 | 14.70 | 16.30 | |

| 6.0-8.0 | 16.90 | 21.20 | 23.50 | |

| 8.0-10 | 28.48 | 37.60 | 41.60 | |

| 10-12 | 43.10 | 58.80 | 65.10 | |

| 12-14 | 60.80 | 84.60 | 93.70 | |

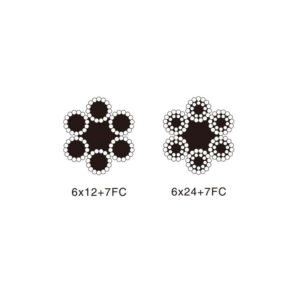

| 6x12+7FC PVC/PP/PE | 2.0-3.0 | 1.57 | 1.48 | 1.64 |

| 3.0-4.0 | 3.06 | 3.33 | 3.69 | |

| 3.0-5.0 | 4.08 | 3.33 | 3.69 | |

| 4.0-5.0 | 5.04 | 5.92 | 6.56 | |

| 4.0-6.0 | 6.29 | 5.92 | 6.56 | |

| 6.0-8.0 | 12.22 | 13.30 | ||

| 8.0-10 | 20.20 | 23.70 |

| Diameter | ||||||||

|---|---|---|---|---|---|---|---|---|

| Inner Cable | Outer Cover | Weight | Breaking Strength | |||||

| Inner Cable | Coating | Total | ||||||

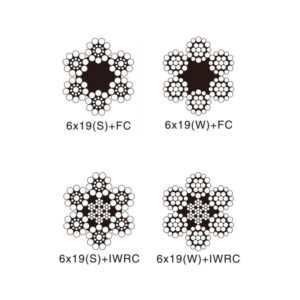

| 7x7(PVC/PP/PE) | Ib/1000' | kg/1000° | Ib/1000° | kg/1000' | Ib/1000° | kg/1000 | Ib | |

| 3/64 | 1/16 | 4.20 | 1.91 | 0.84 | 0.38 | 5.04 | 2.29 | 270 |

| 3/64 | 5v4 | 4.20 | 1.91 | 1.93 | 0.87 | 6.13 | 2.78 | 270 |

| 1/16 | 3/32 | 7.50 | 3.40 | 2.40 | 1.09 | 9.90 | 4.49 | 480 |

| 1/16 | 1/8 | 7.50 | 3.40 | 5.78 | 2.62 | 13.28 | 6.02 | 480 |

| 3/32 | 1/8 | 16.00 | 7.26 | 3.40 | 1.54 | 19.40 | 8.80 | 920 |

| 3/32 | 5/32 | 16.00 | 7.26 | 7.72 | 3.50 | 23.72 | 10.76 | 920 |

| 3/32 | 3/16 | 16.00 | 7.26 | 13.02 | 5.90 | 29.02 | 13.16 | 920 |

| 1/8 | 5/32 | 28.50 | 12.93 | 4.34 | 1.97 | 32.84 | 14.90 | 1700 |

| 1/8 | 3/16 | 28.50 | 12.93 | 9.64 | 4.37 | 38.14 | 17.30 | 1700 |

| 3/16 | 1/4 | 62.00 | 28.12 | 13.50 | 6.12 | 75.50 | 34.24 | 3700 |

| 3/16 | 5/16 | 62.00 | 28.12 | 30.82 | 13.98 | 92.82 | 42.10 | 3700 |

| 7x19(PVC/PP/PE) | ||||||||

| 3/32 | 1/8 | 17.40 | 7.89 | 3.37 | 1.53 | 20.77 | 9.42 | 1000 |

| 3/32 | 5/32 | 17.40 | 7.89 | 7.72 | 3.50 | 25.12 | 11.40 | 1000 |

| 3/32 | 3/16 | 17.40 | 7.89 | 13.02 | 5.91 | 30.42 | 13.80 | 1000 |

| 1/8 | 5/32 | 29.00 | 13.15 | 4.34 | 1.97 | 33.34 | 15.12 | 2000 |

| 1/8 | 3/16 | 29.00 | 13.15 | 9.64 | 4.37 | 38.64 | 17.52 | 2000 |

| 5/32 | 7/32 | 45.00 | 20.14 | 11.56 | 5.24 | 56.56 | 25.65 | 2800 |

| 5/32 | 1/4 | 45.00 | 20.14 | 18.80 | 8.53 | 63.80 | 28.94 | 2800 |

| 3/16 | 1/4 | 65.00 | 29.48 | 13.50 | 6.12 | 78.50 | 35.60 | 4200 |

| 3/16 | 5/16 | 65.00 | 29.48 | 30.82 | 13.98 | 95.82 | 43.46 | 4200 |

| 1/4 | 5/16 | 110.00 | 49.90 | 17.40 | 7.90 | 127.40 | 57.80 | 7000 |

| 1/4 | 3/8 | 110.00 | 49.90 | 38.60 | 17.50 | 148.60 | 67.40 | 7000 |

| 5/16 | 3/8 | 173.00 | 78.47 | 21.20 | 9.63 | 194.20 | 88.10 | 9800 |

| 5/16 | 7/16 | 173.00 | 78.47 | 46.30 | 21.00 | 219.30 | 99.50 | 9800 |

| 3/8 | 7/16 | 243.00 | 110.22 | 25.10 | 11.38 | 268.10 | 121.60 | 14400 |

| 3/8 | 1/2 | 243.00 | 110.22 | 54.00 | 24.48 | 297.00 | 134.70 | 14400 |

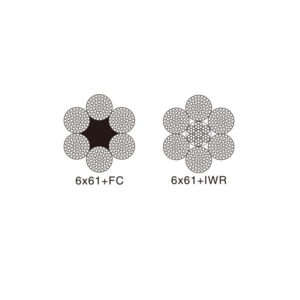

PVC/PP/PE Coated Steel Wire Rope is a versatile and durable solution for various industrial, marine, and construction applications. The steel wire rope, known for its high tensile strength, is coated with either PVC, PP, or PE material, which significantly enhances its resistance to corrosion, abrasion, and environmental damage.

This coating not only protects the wire rope from harsh weather conditions but also provides a smooth surface that prevents damage to the materials being handled or secured. The flexible coating makes the rope easy to handle and install, ensuring secure and reliable performance even in challenging environments.

PVC-coated wire ropes are often used in applications where flexibility and weather resistance are crucial, such as in outdoor settings or in contact with water. PP and PE coatings offer additional benefits like higher chemical resistance and durability, making them suitable for more specialized applications.

These coated steel wire ropes are commonly used in industries such as shipping, construction, mining, and general industrial settings where a combination of strength, flexibility, and resistance to the elements is required.

• Made with high-strength steel wire rope for maximum durability.

• Coated with PVC/PP/PE for enhanced corrosion and abrasion resistance.

• Ideal for industrial, marine, and outdoor applications.

• Available in various diameters and coating thicknesses to meet specific requirements.

• Ensures long-lasting performance in harsh environments.