Description

| Approx | ||||||||

|---|---|---|---|---|---|---|---|---|

| NominalDiameter | Weight | |||||||

| 直径 | kg/100m | 1570N/mm² | 1770N/mm² | 1960N/mm² | ||||

| mm | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS |

| 6 | 14 | 15.5 | 17.5 | 18.5 | 19.8 | 20.9 | 21.9 | 23.1 |

| 7 | 19.1 | 21.1 | 23.8 | 25.2 | 26.9 | 28.4 | 29.8 | 31.5 |

| 8 | 25 | 27.5 | 31.1 | 33 | 35.1 | 37.2 | 38.9 | 41.1 |

| 9 | 31.6 | 34.8 | 39.4 | 41.7 | 44.4 | 47 | 49.2 | 52.1 |

| 10 | 39 | 43 | 48.7 | 51.5 | 54.9 | 58.1 | 60.8 | 64.3 |

| 11 | 47.2 | 52 | 58.9 | 62.3 | 66.4 | 70.2 | 73.5 | 77.8 |

| 12 | 56.2 | 61.9 | 70.1 | 74.2 | 79 | 83.6 | 87.5 | 92.6 |

| 13 | 65.9 | 72.7 | 82.3 | 87 | 92.7 | 98.1 | 103 | 109 |

| 14 | 76.4 | 84.3 | 95.4 | 101 | 108 | 114 | 119 | 126 |

| 16 | 99.8 | 110 | 125 | 132 | 140 | 149 | 156 | 165 |

| 18 | 126 | 139 | 158 | 167 | 178 | 188 | 197 | 208 |

| 20 | 156 | 172 | 195 | 206 | 219 | 232 | 243 | 257 |

| 22 | 189 | 208 | 236 | 249 | 266 | 281 | 294 | 311 |

| 24 | 225 | 248 | 280 | 297 | 316 | 334 | 350 | 370 |

| 26 | 264 | 291 | 329 | 348 | 371 | 392 | 411 | 435 |

| 28 | 306 | 337 | 382 | 404 | 430 | 455 | 476 | 504 |

| 30 | 351 | 387 | 438 | 463 | 494 | 523 | 547 | 579 |

| 32 | 399 | 440 | 498 | 527 | 562 | 594 | 622 | 658 |

| 34 | 451 | 497 | 563 | 595 | 634 | 671 | 702 | 743 |

| 36 | 505 | 557 | 631 | 667 | 711 | 752 | 787 | 833 |

| 38 | 563 | 621 | 703 | 744 | 792 | 838 | 877 | 928 |

| 40 | 624 | 688 | 779 | 824 | 878 | 929 | 972 | 1030 |

| 42 | 688 | 759 | 859 | 908 | 968 | 1020 | 1070 | 1130 |

| 44 | 755 | 832 | 942 | 997 | 1060 | 1120 | 1180 | 1240 |

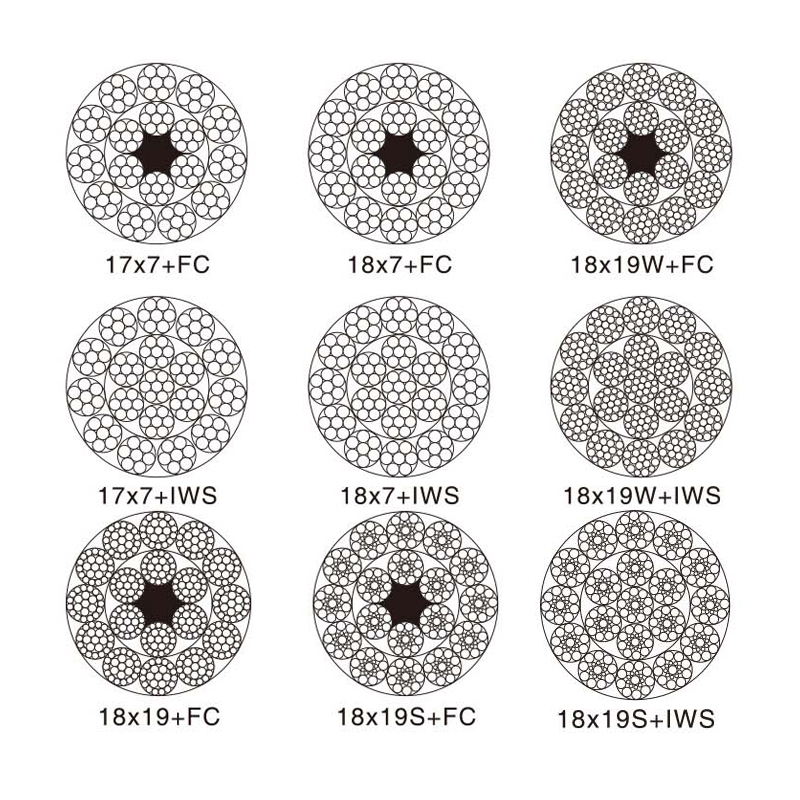

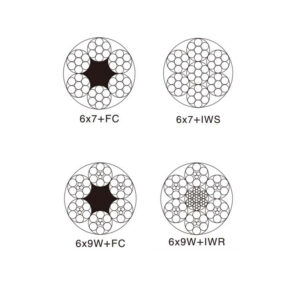

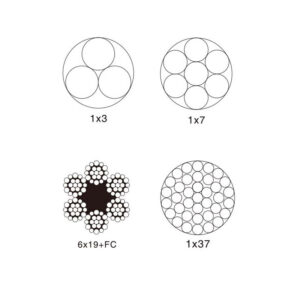

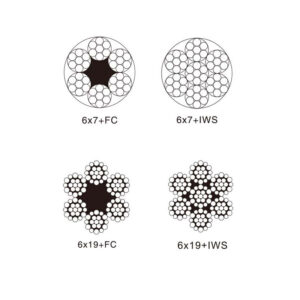

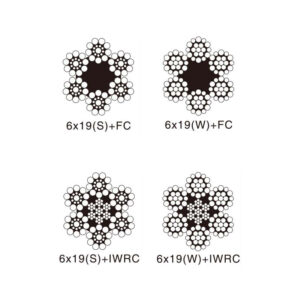

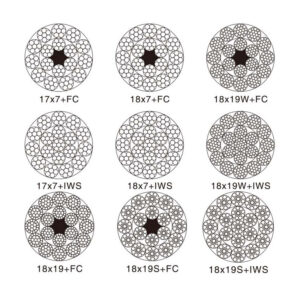

Non-Rotating Steel Wire Ropes (Ungalvanized and Galvanized) are engineered for specialized applications where load stability and safety are critical. These ropes are designed with a specific construction, such as 18×7+FC and 35Wx7, to minimize the rotational effect that can occur when lifting heavy loads. This makes them particularly suitable for use in environments like ports, tower cranes, elevators, and other industrial machinery where precise load control is essential.

The ropes are available in both ungalvanized and galvanized versions, offering flexibility depending on the application. Galvanized ropes, treated with either electric or hot-dipped galvanization, provide enhanced corrosion resistance, making them ideal for use in harsh environments.

Constructed with either fiber cores (FC) or independent wire rope cores (IWRC), these non-rotating ropes offer high tensile strength and durability, with specific models capable of withstanding significant shock loads and compressive forces, such as those experienced by excavators and other heavy machinery. The ropes are available in various sizes and configurations to meet the needs of different lifting and hoisting operations.

• Available in both ungalvanized and galvanized finishes for varied applications.

• Constructed with fiber core (FC) or independent wire rope core (IWRC) for enhanced durability.

• Designed to reduce rotation under load, ensuring stability during lifting operations.

• Suitable for use in harsh environments, with options for electric or hot-dipped galvanization.