Description

| Nominal | Appro | Nominal Tensile Strength | ||||

|---|---|---|---|---|---|---|

| Construction | 0hmle | Weight | Minium Breaking Strength (kN) | |||

| mm | kg/100m | 1570N/mm² | 1770N/mm² | 1870N/mm | 1960Mmo | |

| 8 | 29.4 | 36.1 | 40.7 | 43.0 | 45.1 | |

| 10 | 46 | 56.5 | 63.7 | 67.3 | 70.6 | |

| 12 | 66.2 | 81.4 | 91.8 | 96.9 | 102 | |

| 14 | 90.2 | 111 | 125 | 132 | 138 | |

| 16 | 118 | 145 | 163 | 172 | 181 | |

| 18 | 149 | 183 | 206 | 218 | 229 | |

| 20 | 184 | 226 | 255 | 269 | 282 | |

| 22 | 223 | 274 | 308 | 326 | 342 | |

| 24 | 265 | 326 | 367 | 388 | 406 | |

| 26 | 311 | 382 | 431 | 455 | 477 | |

| 28 | 361 | 443 | 500 | 528 | 553 | |

| 35W*7 | 30 | 414 | 509 | 573 | 606 | 635 |

| 32 | 471 | 579 | 652 | 689 | 723 | |

| 34 | 532 | 653 | 737 | 778 | 816 | |

| 36 | 596 | 732 | 826 | 872 | 914 | |

| 38 | 664 | 816 | 920 | 972 | 1020 | |

| 40 | 736 | 904 | 1020 | 1080 | 1130 | |

| 42 | 811 | 997 | 1120 | 1190 | 1240 | |

| 44 | 891 | 1090 | 1230 | 1300 | 1370 | |

| 46 | 973 | 1196 | 1348 | 1424 | 1493 | |

| 48 | 1060 | 1302 | 1468 | 1551 | 1625 | |

| 50 | 1150 | 1410 | 1590 | 1680 | 1760 | |

| Nominal | Appro | Nominal Tensile Strength | ||||

| Construction | 0hmle | Weight | Minium Breaking Strength (kN) | |||

| mm | kg/100m | 1570N/mm² | 1770N/mm² | 1870N/mm | 1960Mmo | |

| 8 | 24.96 | 32.0 | 36.1 | 38.1 | 39.9 | |

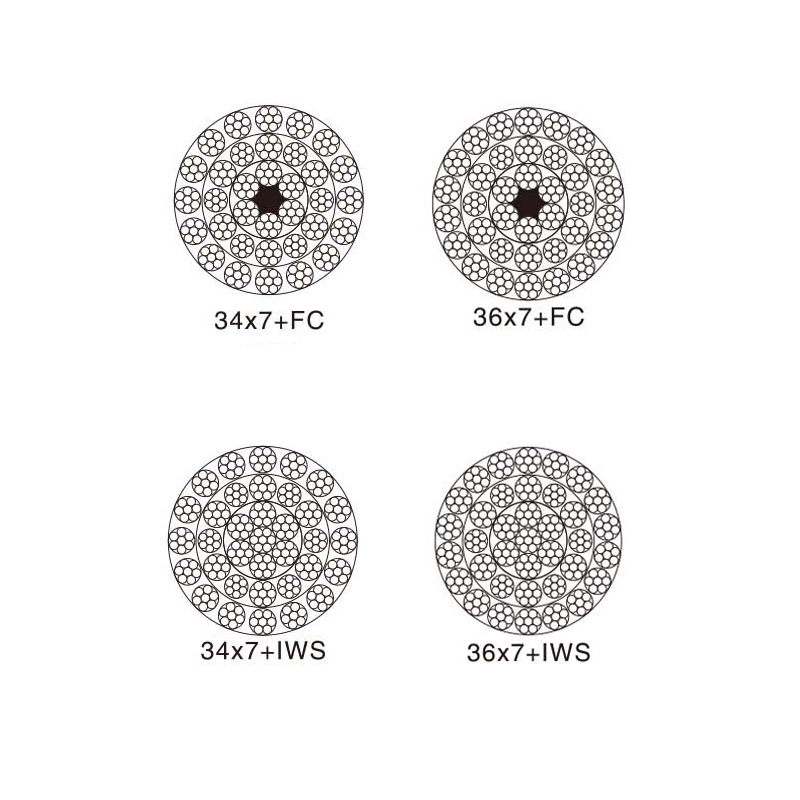

| 34*7+FC | 10 | 39.00 | 50.0 | 56.3 | 59.5 | 62.4 |

| 12 | 56.16 | 72.0 | 81.1 | 85.7 | 89.8 | |

| 14 | 76.44 | 98.0 | 111 | 117 | 123 | |

| 16 | 99.84 | 128 | 144 | 153 | 160 | |

| 18 | 126.36 | 162 | 182 | 193 | 202 | |

| 34*7+IWS | 20 | 156 | 200 | 225 | 238 | 250 |

| 24 | 225 | 288 | 325 | 343 | 360 | |

| 28 | 306 | 392 | 442 | 467 | 489 | |

| 36*7+FC | 30 | 351 | 450 | 507 | 536 | 561 |

| 36 | 506 | 648 | 730 | 771 | 808 | |

| 42 | 688 | 881 | 993 | 1049 | 1100 | |

| 36*7+IWS | 48 | 900 | 1151 | 1297 | 1370 | 1437 |

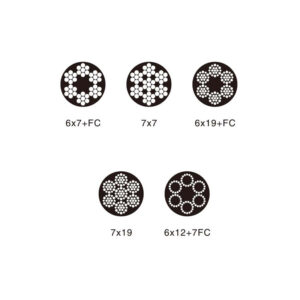

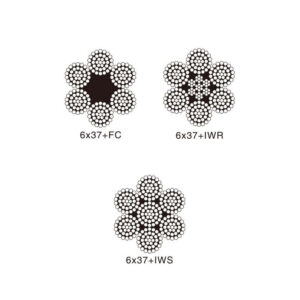

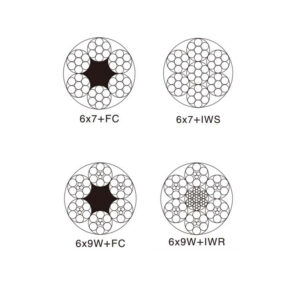

The NON-Rotating Steel Wire Rope is specifically designed to reduce the tendency to rotate or spin under load, making it an essential component for lifting, hoisting, and crane applications where maintaining load stability is critical. This type of wire rope is manufactured using a specialized construction that counteracts rotational forces, ensuring safer and more efficient operations.

Available in both ungalvanized and galvanized finishes, this wire rope caters to a wide range of operational environments:

- Ungalvanized Wire Rope: Offers high strength and is suitable for applications where exposure to the elements is minimal. It is often preferred for indoor use or situations where frequent replacement is feasible.

- Galvanized Wire Rope: Features a zinc coating that provides excellent corrosion resistance, making it ideal for outdoor applications and environments where the rope is exposed to moisture, chemicals, or harsh weather conditions. The galvanized finish extends the rope’s service life by protecting it from rust and corrosion.

The NON-Rotating Steel Wire Rope is widely used in construction, marine, oil and gas, and other industrial sectors where precise and secure lifting is essential. The rope is available in various diameters and constructions to meet specific load requirements and operational conditions.

Key Features:

- Non-Rotating Construction: Designed to minimize rotation, ensuring stability during lifting operations.

- Surface Finish: Available in both ungalvanized and galvanized options for different environmental conditions.

- High Strength: Manufactured from high-quality steel, offering superior tensile strength and durability.

- Versatile Applications: Ideal for use in cranes, winches, hoisting systems, and other critical lifting equipment.

- Corrosion Resistance: Galvanized ropes offer enhanced protection against rust, extending the rope’s operational life.

Whether you’re operating in a controlled indoor environment or a challenging outdoor setting, the NON-Rotating Steel Wire Rope delivers reliable performance, safety, and longevity, making it a preferred choice for professionals across various industries.