Description

| Approx | ||||||||

|---|---|---|---|---|---|---|---|---|

| NominalDiameter | Weight | |||||||

| kg/100m | 1570N/mm² | 1770N/mm² | 1960N/mm² | |||||

| mm | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS |

| 8 | 22.98/22.00 | 27.90 | 29.30 | 34.70 | 33.10 | 39.10 | 36.70 | 43.40 |

| 9 | 29.00/27.80 | 35.30 | 37.10 | 43.90 | 41.90 | 49.50 | 46.50 | 54.90 |

| 10 | 35.90/34.40 | 43.60 | 45.80 | 54.20 | 51.70 | 61.10 | 57.40 | 67.80 |

| 11 | 43.30/42.60 | 52.70 | 55.50 | 65.50 | 62.60 | 73.90 | 69.50 | 82.00 |

| 12 | 51.50/49.50 | 62.80 | 66.00 | 79.00 | 74.50 | 88.00 | 82.70 | 97.60 |

| 13 | 60.40/58.10 | 73.60 | 77.50 | 91.50 | 87.40 | 103 | 97.00 | 114 |

| 14 | 70.10/67.40 | 85.40 | 89.80 | 106 | 101 | 120 | 112 | 133 |

| 16 | 91.60/88.00 | 111 | 117 | 139 | 132 | 156 | 147 | 173 |

| 18 | 116/111 | 141 | 149 | 176 | 168 | 198 | 186 | 220 |

| 20 | 143/138 | 174 | 184 | 217 | 207 | 224 | 230 | 271 |

| 22 | 173/166 | 210 | 222 | 262 | 250 | 296 | 278 | 328 |

| 24 | 206/198 | 251 | 264 | 312 | 298 | 352 | 330 | 390 |

| 26 | 242/232 | 295 | 310 | 367 | 350 | 413 | 388 | 458 |

| 28 | 280/270 | 342 | 360 | 425 | 406 | 480 | 450 | 531 |

| 30 | 322/310 | 392 | 414 | 488 | 446 | 551 | 516 | 610 |

| 32 | 366/352 | 446 | 471 | 556 | 531 | 627 | 588 | 694 |

| 34 | 414/398 | 504 | 532 | 628 | 600 | 707 | 663 | 784 |

| 36 | 464/446 | 565 | 596 | 704 | 672 | 793 | 744 | 878 |

| 38 | 517/497 | 630 | 664 | 784 | 748 | 884 | 829 | 979 |

| 40 | 572/550 | 698 | 736 | 869 | 830 | 979 | 918 | 1085 |

| 42 | 631/607 | 769 | 811 | 958 | 914 | 1080 | 1013 | 1196 |

| 44 | 693/666 | 844 | 890 | 1051 | 1004 | 1185 | 11 | 1312 |

| 46 | 757/730 | 922 | 973 | 1140 | 1090 | 1295 | 1215 | 1434 |

| 48 | 825/793 | 1004 | 1050 | 1251 | 14194 | 1411 | 1323 | 1562 |

| 50 | 895/860 | 1090 | 1150 | 1358 | 1296 | 1531 | 1435 | 1695 |

| 52 | 968/930 | 1179 | 1243 | 1468 | 1402 | 1655 | 1552 | 1833 |

| 54 | 1044/1003 | 1271 | 1341 | 1584 | 1512 | 1785 | 1674 | 1977 |

| 56 | 1122/1079 | 1367 | 1442 | 1703 | 1626 | 1920 | 1800 | 2126 |

| 58 | 1204/1157 | 1466 | 1547 | 1827 | 1744 | 2060 | 1931 | 2281 |

| 60 | 1288/1238 | 1570 | 1656 | 1955 | 1866 | 2204 | 2067 | 2441 |

| 62 | 1376/1322 | 1676 | 1768 | 2088 | 1996 | 2354 | 2207 | 2606 |

| 64 | 1466/1410 | 1886 | 1884 | 2225 | 2124 | 2500 | 2352 | 2777 |

| 66 | 1560/1498 | 1900 | 2004 | 2366 | 2259 | 2667 | 2501 | 2954 |

| 68 | 1655/1590 | 2016 | 2127 | 2511 | 2398 | 2831 | 2655 | 3135 |

| 70 | 1754/1685 | 2136 | 2254 | 2661 | 2541 | 3000 | 2814 | 3322 |

| 72 | 1855/1783 | 2260 | 2384 | 2816 | 2688 | 3174 | 2977 | 3515 |

| 74 | 1960/1884 | 2388 | 2519 | 2974 | 2840 | 3353 | 3144 | 3713 |

| 76 | 2067/1987 | 2518 | 2657 | 3137 | 2995 | 3537 | 3317 | 3917 |

| 78 | 2178/2092 | 2652 | 2798 | 3304 | 3155 | 3725 | 3494 | 4125 |

| 80 | 2291/2201 | 2790 | 2944 | 3476 | 3319 | 3919 | 3675 | 4340 |

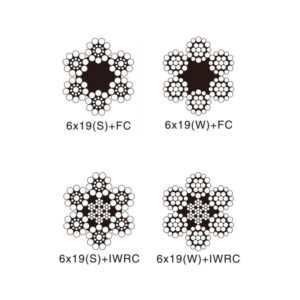

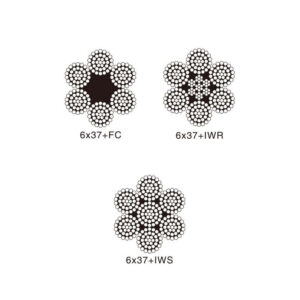

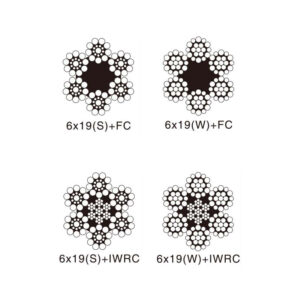

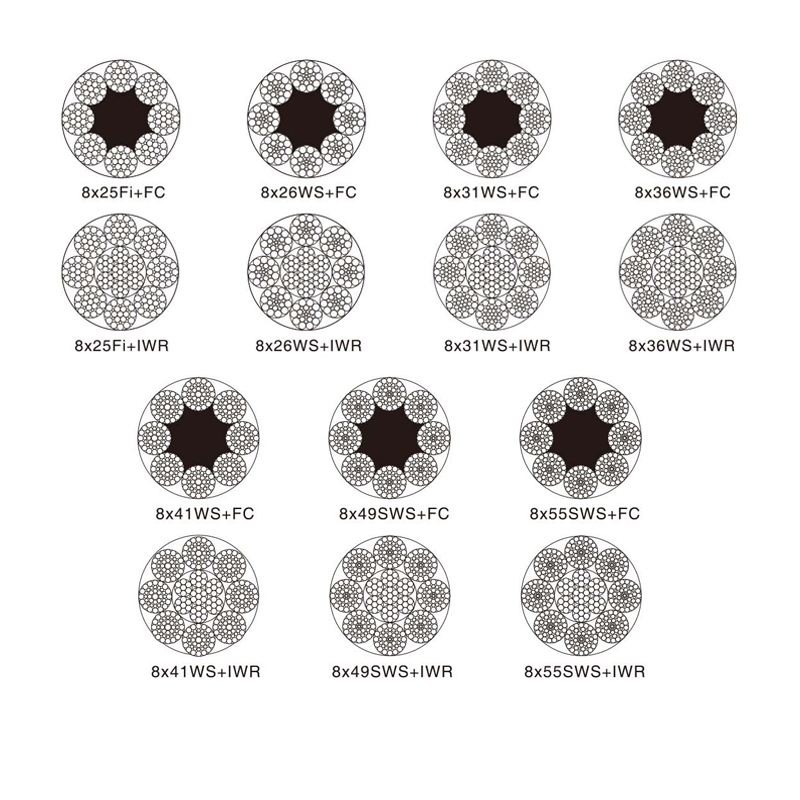

Line Contacted Steel Wire Rope (Ungalvanized and Galvanized) is designed for superior strength and durability, making it ideal for heavy-duty industrial applications. This wire rope is available in different constructions, including 6×19(S), 6x25Fi, 6x36WS, and others, with options for both fiber core (FC) and independent wire rope core (IWRC). The ropes are offered in either ungalvanized or galvanized finishes, including electric galvanized and hot-dipped galvanized, providing excellent corrosion resistance.

The versatile applications of this wire rope include vertical well hoisting, blast furnace winching, oil well drilling, belt conveyor operations, and cable traction. The steel core variants are especially suitable for conditions involving shock loads, heat, and compression, making them an excellent choice for equipment like excavators and cranes.

This steel wire rope is manufactured to meet industry standards, ensuring consistent performance and safety in challenging environments. With high tensile strength and a robust construction, it is a reliable choice for professionals in mining, construction, and industrial sectors.

• Available in various constructions, including 6×19(S), 6x25Fi, and 6x36WS.

• Offered in ungalvanized, electric galvanized, and hot-dipped galvanized finishes.

• Suitable for heavy-duty applications like hoisting, drilling, and cable traction.

• High tensile strength ensures reliability and durability in demanding environments.

• Meets industry standards for safety and performance.