Description

| Approx | ||||||||

|---|---|---|---|---|---|---|---|---|

| NominalDiameter | Weight | |||||||

| kg/100m | 1570N/mm² | 1770N/mm² | 1960N/mm² | |||||

| mm | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS |

| 6 | 13.70/13.40 | 15.00 | 18.60 | 20.10 | 21.00 | 22.60 | 23.20 | 25.10 |

| 8 | 24.30/23.70 | 26.80 | 33.20 | 35.80 | 37.40 | 40.30 | 41.40 | 44.60 |

| 9 | 30.80/30.10 | 33.90 | 42.00 | 45.30 | 47.30 | 51.00 | 52.30 | 56.50 |

| 10 | 38.00/37.10 | 41.80 | 51.80 | 55.90 | 58.40 | 63.00 | 64.60 | 69.70 |

| 11 | 46.00/44.90 | 50.60 | 62.70 | 67.60 | 70.70 | 76.20 | 78.20 | 84.40 |

| 12 | 54.70/53.40 | 60.20 | 74.60 | 80.50 | 84.10 | 90.70 | 93.10 | 100 |

| 13 | 64.20/62.70 | 70.60 | 87.60 | 94.50 | 98.70 | 106 | 109 | 118 |

| 14 | 74.50/72.70 | 81.90 | 102 | 110 | 114 | 124 | 126 | 136 |

| 16 | 97.30/95.00 | 107 | 133 | 143 | 150 | 161 | 165 | 178 |

| 18 | 123/120 | 135 | 168 | 181 | 189 | 204 | 209 | 226 |

| 20 | 152/148 | 167 | 207 | 224 | 234 | 252 | 258 | 279 |

| 22 | 184/180 | 202 | 251 | 271 | 283 | 305 | 313 | 337 |

| 24 | 219/214 | 241 | 298 | 322 | 336 | 363 | 372 | 402 |

| 26 | 257/251 | 283 | 350 | 378 | 395 | 426 | 437 | 471 |

| 28 | 298/291 | 328 | 406 | 438 | 458 | 494 | 507 | 547 |

| 30 | 342/334 | 376 | 466 | 503 | 526 | 567 | 582 | 627 |

| 32 | 389/380 | 428 | 531 | 572 | 598 | 645 | 662 | 714 |

| 34 | 439/429 | 483 | 599 | 646 | 675 | 728 | 747 | 806 |

| 36 | 492/481 | 542 | 671 | 724 | 757 | 817 | 838 | 904 |

| 38 | 549/536 | 604 | 748 | 807 | 843 | 910 | 933 | 1007 |

| 40 | 608/594 | 669 | 829 | 894 | 935 | 1010 | 1034 | 1116 |

| 42 | 670/654 | 737 | 914 | 986 | 1030 | 1110 | 1140 | 1230 |

| 44 | 736/718 | 809 | 1000 | 1080 | 1130 | 1220 | 1252 | 1350 |

| 46 | 804/785 | 884 | 1100 | 1180 | 1240 | 1330 | 1368 | 1476 |

| 48 | 876/855 | 963 | 1190 | 1290 | 1350 | 1450 | 1490 | 1607 |

| 50 | 950/928 | 1050 | 1300 | 1400 | 1460 | 1580 | 1617 | 1744 |

| 52 | 1030/1000 | 1130 | 1400 | 1510 | 1580 | 1700 | 1748 | 1686 |

| 54 | 1110/1080 | 1220 | 1510 | 1630 | 1700 | 1840 | 1886 | 2034 |

| 56 | 1190/1160 | 1310 | 1620 | 1750 | 1830 | 1980 | 2028 | 2188 |

| 58 | 1280/1250 | 1410 | 1740 | 1880 | 1960 | 2120 | 2175 | 2347 |

| 60 | 1370/1340 | 1500 | 1870 | 2010 | 2100 | 2270 | 2328 | 2511 |

| 62 | 1460/1430 | 1610 | 1990 | 2150 | 2250 | 2420 | 2486 | 2682 |

| 65 | 1606/1567 | 1766 | 2188 | 2361 | 2467 | 2662 | 2732 | 2948 |

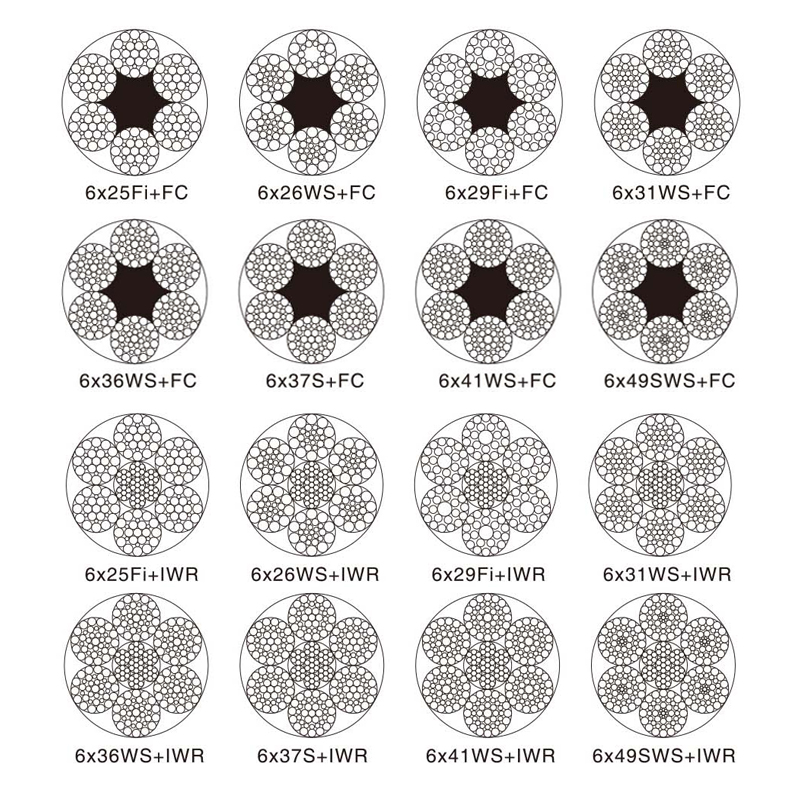

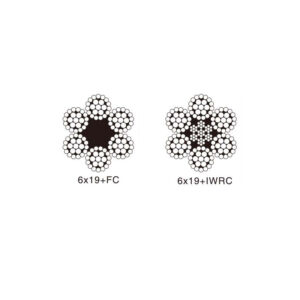

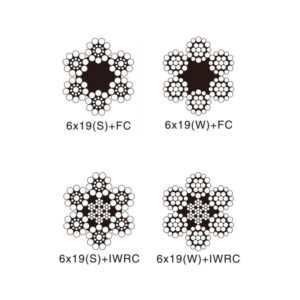

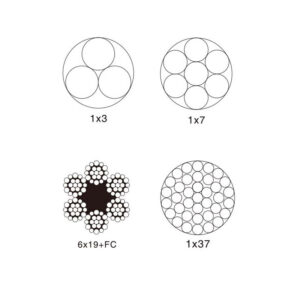

The Line Contacted Steel Wire Rope 6×25 Fi – 6×55 SWS + IWR is designed for superior performance in heavy-duty lifting and hoisting operations. This specialized wire rope features a unique construction, where each wire strand is in line contact with its adjacent strands, significantly enhancing its strength and durability.

- 6×25 Fi Construction: This configuration includes six strands, each consisting of 25 wires. The ‘Fi’ (Filler Wire) design ensures that the rope has a high resistance to abrasion and crushing, making it suitable for use in pulleys and other high-pressure environments. The filler wires add strength and help to maintain the rope’s shape under load.

- 6×55 SWS Construction: This variant features six strands, each composed of 55 wires in a Seale Wire Strand (SWS) configuration. The SWS design provides excellent flexibility and fatigue resistance, ideal for operations requiring frequent bending or winding.

- Independent Wire Rope Core (IWR): The IWR core enhances the rope’s overall strength and resistance to crushing, making it more durable and suitable for demanding applications. The IWR also contributes to maintaining the rope’s shape under heavy loads, providing consistent performance over time.

This steel wire rope is commonly used in industries such as construction, mining, and marine, where reliable and durable lifting equipment is essential. The rope is available in various diameters and lengths to accommodate different operational requirements.

Key Features:

- Line Contacted Construction: Ensures each wire strand is in line contact, enhancing the rope’s strength and lifespan.

- 6×25 Fi and 6×55 SWS Configurations: Provides a balance of strength, flexibility, and abrasion resistance.

- Independent Wire Rope Core (IWR): Offers superior load-bearing capacity and resistance to deformation under heavy loads.

- High Strength and Durability: Suitable for use in demanding industrial applications.

- Versatile Applications: Ideal for lifting, hoisting, and rigging in construction, mining, and marine environments.

Whether used in cranes, winches, or other heavy machinery, the Line Contacted Steel Wire Rope 6×25 Fi – 6×55 SWS + IWR provides reliable performance, safety, and durability in various industrial settings.