Description

| Dimension(mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size | W.L.L(t) | B.L(t) | N.W.(kg/pc) | ||||||

| A | B | D | a | b | d | ||||

| 6-10 | 3.5 | 14 | 150 | 90 | 19 | 120 | 70 | 14 | 1.8 |

| 8-10 | 5 | 20 | 160 | 95 | 22 | 140 | 80 | 17 | 3.0 |

| 10-10 | 11.5 | 46 | 200 | 120 | 30 | 160 | 95 | 22 | 6.5 |

| 13-10 | 17 | 68 | 250 | 150 | 40 | 200 | 120 | 30 | 15 |

| 16-10 | 28 | 112 | 300 | 200 | 50 | 200 | 120 | 32 | 23 |

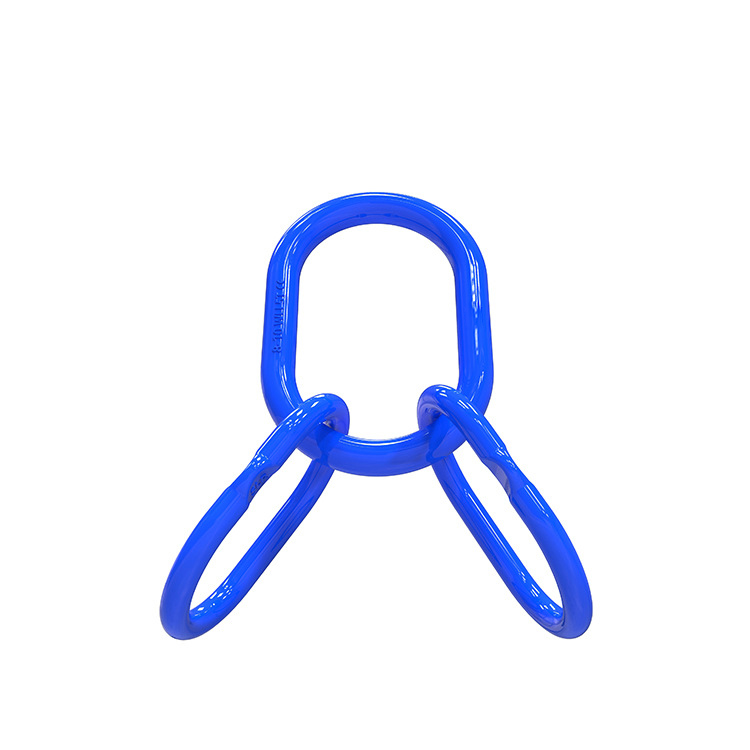

The G100 Master Link Assembly with Flat (TH-1015) is a robust and reliable component designed specifically for demanding lifting and rigging applications. Manufactured from high-strength alloy steel, this assembly is heat-treated to ensure maximum durability and load-bearing capacity, making it ideal for use in construction, shipping, and industrial environments.

This master link assembly features a flat design, which enhances load distribution across the link and ensures a secure connection with slings, hooks, and other rigging hardware. The flat section also allows for easy stacking and efficient use in multi-leg sling assemblies, contributing to safer and more efficient lifting operations.

Compliant with G100 standards, the TH-1015 assembly is engineered to withstand the rigors of heavy-duty use, offering exceptional resistance to wear, impact, and deformation. The assembly is also designed to accommodate large chain sizes, making it versatile for various lifting configurations.

- Material: High-strength alloy steel, quenched and tempered for enhanced durability.

- Surface Finish: Available in powder-coated finish for corrosion resistance.

- Application: Ideal for heavy lifting, rigging, and multi-leg sling assemblies in industrial and construction settings.

- Features: Flat design for optimal load distribution and secure connection with rigging components.

For more information on our G100 Master Link Assembly with Flat (TH-1015), or to discuss your specific lifting needs, please contact our team. We are here to provide expert guidance and support.