Description

| Nominal | Approx | Minimum Breaking Strength(kN) | ||||||

|---|---|---|---|---|---|---|---|---|

| Dlamote | Weight | Double Strength(Mpa) | Sngle Strength (Mpa) | |||||

| mm | kg/100m | 1180/1770 | 1320/1620 | 1370/1770 | 1570/1770 | 1570 | 1620 | 1770 |

| 6 | 12.9 | 16.3 | 16.8 | 17.8 | 19.5 | 18.7 | 19.2 | 21.0 |

| 6.3 | 14.2 | 17.9 | 21.5 | 21.2 | 23.2 | |||

| 6.5 | 15.2 | 19.1 | 19.7 | 20.9 | 22.9 | 21.9 | 22.6 | 24.7 |

| 8 | 23.0 | 28.9 | 29.8 | 31.7 | 34.6 | 33.2 | 34.2 | 37.4 |

| 9 | 29.1 | 36.6 | 37.7 | 40.1 | 43.8 | 42.0 | 43.3 | 47.3 |

| 9.5 | 32.4 | 40.8 | 42.0 | 44.7 | 48.8 | 46.8 | 48.2 | 52.7 |

| 10 | 35.9 | 45.2 | 46.5 | 49.5 | 54.1 | 51.8 | 53.5 | 58.4 |

| 11 | 43.4 | 54.7 | 54.3 | 59.9 | 65.5 | 62.7 | 64.7 | 70.7 |

| 12 | 51.7 | 65.1 | 62.0 | 71.3 | 77.9 | 74.6 | 77.0 | 84.1 |

| 12.7 | 57.9 | 72.9 | 75.0 | 79.8 | 87.3 | 83.6 | 86.2 | 94.2 |

| 13 | 60.7 | 76.4 | 78.6 | 83.7 | 91.5 | 87.6 | 90.3 | 98.7 |

| 14 | 70.4 | 88.6 | 91.2 | 97.0 | 106 | 102 | 105 | 114 |

| 14.3 | 73.4 | 92.4 | 111 | 119 | ||||

| 15 | 80.8 | 102 | - | 111 | 122 | 117 | 131 | |

| 16 | 91.9 | 116 | 119 | 127 | 139 | 133 | 137 | 150 |

| 17.5 | 110 | 138 | 166 | 179 | ||||

| 18 | 116 | 146 | 151 | 160 | 175 | 168 | 173 | 189 |

| 19 | 130 | 163 | 168 | 179 | 195 | 187 | 193 | 211 |

| 20 | 144 | 181 | 186 | 198 | 216 | 207 | 214 | 234 |

| 20.6 | 152 | 192 | 230 | 248 | ||||

| 22 | 174 | 219 | 225 | 240 | 262 | 251 | 259 | 283 |

| 8 | 21.8 | 25.7 | 26.5 | 28.1 | 30.8 | 29. | 30.4 | 33.2 |

| 9 | 27.5 | 32.5 | 35.6 | 38.9 | 37.3 | 42 | ||

| 9.5 | 30.7 | 36.2 | 37.3 | 39.7 | 43.6 | 41.5 | 42.8 | 46.8 |

| 10 | 34.0 | 40.1 | 41.3 | 44.0 | 48.1 | 46.0 | 47.5 | 51.9 |

| 11 | 41.1 | 48.6 | 50.0 | 53.2 | 58.1 | 55.7 | 57.4 | 62.8 |

| 12 | 49.0 | 57.8 | 59.5 | 63.3 | 69.2 | 66.2 | 68.4 | 74.7 |

| 12.7 | 54.8 | 64.7 | 66.6 | 70.9 | 77.5 | 74.2 | 76.6 | 83.6 |

| 13 | 57.5 | 67.8 | 69.8 | 74.3 | 81.2 | 77.7 | 80.2 | 87.6 |

| 14 | 66.6 | 78.7 | 81.0 | 86.1 | 94.2 | 90.2 | 93.0 | 102 |

| 14.3 | 69.5 | 82.1 | 98.9 | 98.3 | 104 | |||

| 15 | 76.5 | 90.3 | 106 | 113 | 108 | 118 | 117 | |

| 16 | 87.0 | 103 | 134 | 123 | 122 | 133 | ||

| 17.5 | 104 | 123 | 149 | 142 | 147 | 149 | ||

| 18 | 110 | 130 | 165 | 159 | 156 | 166 | 154 | 168 |

| 19 | 123 | 145 | 176 | 173 | 184 | 171 | 187 | |

| 20 | 136 | 161 | 200 | 213 | 192 | 190 | 207 | |

| 20.6 | 144 | 170 | 204 | 223 | ||||

| 22 | 165 | 194 | 233 | 230 | 251 |

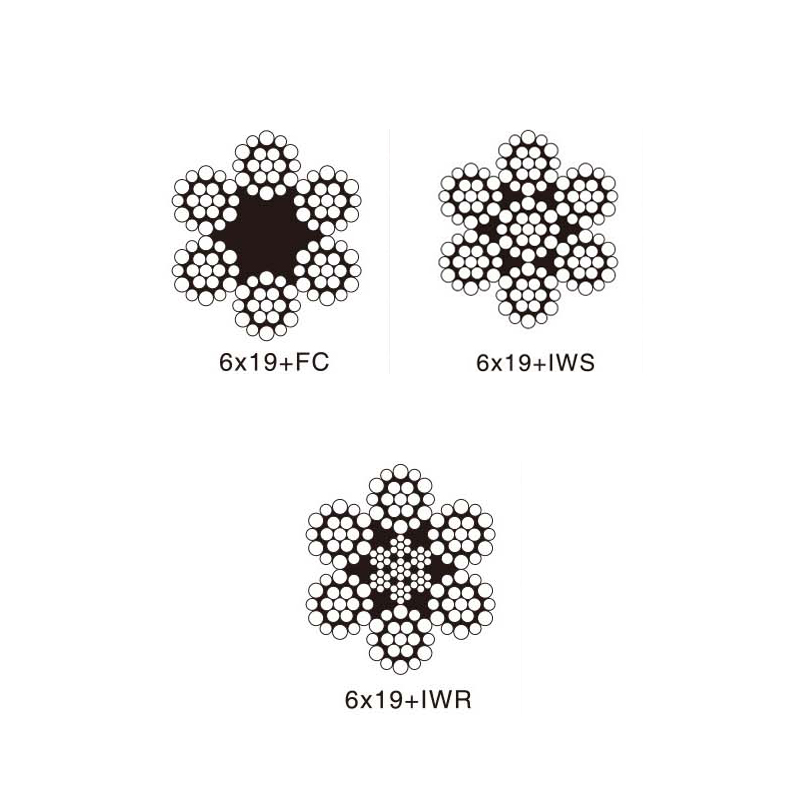

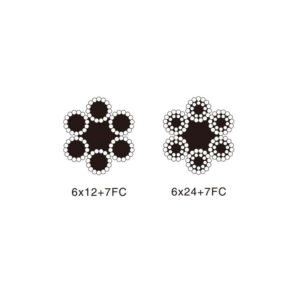

The DIN 3055 Steel Wire Rope 6×19+FC / IWS or IWR is designed to meet the highest standards of performance and reliability for various lifting, rigging, and hoisting applications. This steel wire rope is constructed with six strands, each containing 19 wires, making it highly flexible and durable. The rope is available in two core types: Fiber Core (FC) and Independent Wire Rope Core (IWRC/IWS).

- Fiber Core (FC): The fiber core provides excellent flexibility, making the rope easier to handle and suitable for applications where bending is frequent. The fiber core also helps in absorbing shock loads, which is ideal for general-purpose use.

- Independent Wire Rope Core (IWRC/IWS): The IWRC/IWS core offers enhanced strength and durability, making the rope more resistant to crushing and suitable for more demanding applications. This core type is preferred when higher load capacities and increased resistance to deformation are required.

This steel wire rope is manufactured in compliance with DIN 3055 standards, ensuring consistent quality and performance. It is commonly used in construction, mining, shipping, and various industrial applications. The rope is available in various diameters and lengths to suit different operational needs.

Key Features:

- Construction: 6×19 with either Fiber Core (FC) or Independent Wire Rope Core (IWRC/IWS)

- Standards Compliance: DIN 3055

- Applications: Lifting, rigging, hoisting, and general-purpose use

- Material: High-quality steel for enhanced strength and durability

- Flexibility: High flexibility with FC, higher strength with IWRC/IWS

- Corrosion Resistance: Available with galvanization or uncoated

Whether used for cranes, winches, or other heavy-duty machinery, the DIN 3055 Steel Wire Rope 6×19+FC / IWS or IWR provides reliable performance, safety, and durability in various industrial environments.