Description

| Approx | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| NominalDiameter | Weight | ||||||||

| Construction | kg/100m | 1570N/mm² | 1770N/mm² | 1960N/mm² | |||||

| mm | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS | |

| 5 | 9.20/9.00 | 10.10 | 13.00 | 14.00 | 14.60 | 15.80 | 16.10 | 17.40 | |

| 6 | 13.30/13.00 | 14.60 | 18.70 | 20.10 | 21.00 | 22.70 | 23.20 | 25.10 | |

| 7 | 18.10/17.60 | 19.90 | 25.40 | 27.40 | 28.60 | 30.90 | 31.70 | 34.20 | |

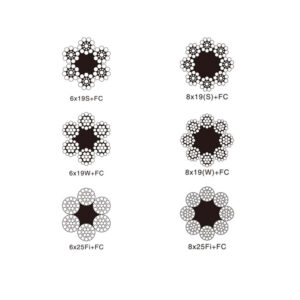

| 6*19(S)+FC | 8 | 23.60/23.00 | 25.90 | 33.20 | 35.80 | 37.40 | 40.30 | 41.30 | 44.60 |

| 9 | 29.90/29.10 | 32.80 | 42.00 | 45.30 | 47.30 | 51.00 | 52.30 | 56.50 | |

| 10 | 36.90/36.00 | 40.50 | 51.80 | 55.90 | 58.40 | 63.00 | 64.60 | 69.70 | |

| 11 | 44.60/43.50 | 49.10 | 62.70 | 67.60 | 70.70 | 76.20 | 78.20 | 84.40 | |

| 12 | 53.10/51.80 | 58.40 | 74.60 | 80.50 | 84.10 | 90.70 | 93.10 | 100 | |

| 13 | 62.30/60.80 | 68.50 | 87.60 | 94.50 | 98.70 | 106 | 109 | 118 | |

| 14 | 72.20/70.50 | 79.50 | 102 | 110 | 114 | 124 | 126 | 136 | |

| 16 | 94.40/92.10 | 104 | 133 | 143 | 150 | 161 | 165 | 178 | |

| 18 | 119/117 | 131 | 168 | 181 | 189 | 204 | 209 | 226 | |

| 6*19(W)+FC | 20 | 147/144 | 162 | 207 | 224 | 234 | 252 | 258 | 279 |

| 22 | 178/174 | 196 | 251 | 271 | 283 | 305 | 313 | 337 | |

| 24 | 212/207 | 234 | 298 | 322 | 336 | 363 | 372 | 402 | |

| 26 | 249/243 | 274 | 350 | 378 | 395 | 426 | 437 | 471 | |

| 28 | 289/282 | 318 | 406 | 438 | 458 | 494 | 507 | 547 | |

| 30 | 332/324 | 365 | 466 | 503 | 526 | 567 | 582 | 627 | |

| 32 | 377/369 | 415 | 531 | 572 | 598 | 645 | 662 | 714 | |

| 6*19(S)+IWRC | 34 | 426/416 | 469 | 599 | 646 | 675 | 728 | 747 | 806 |

| 36 | 478/466 | 525 | 671 | 724 | 757 | 817 | 838 | 904 | |

| 38 | 532/520 | 585 | 748 | 807 | 843 | 910 | 933 | 1007 | |

| 40 | 590/576 | 649 | 829 | 894 | 935 | 1010 | 1034 | 1116 | |

| 42 | 650/635 | 715 | 914 | 986 | 1030 | 1110 | 1140 | 1230 | |

| 6*19(W)+IWRC | 44 | 714/697 | 785 | 1000 | 1080 | 1130 | 1220 | 1252 | 1350 |

| 46 | 780/761 | 858 | 1100 | 1180 | 1240 | 1330 | 1368 | 1476 | |

| 48 | 849/829 | 934 | 1190 | 1290 | 1350 | 1450 | 1490 | 1607 | |

| 50 | 922/900 | 1010 | 1300 | 1400 | 1460 | 1580 | 1617 | 1744 |

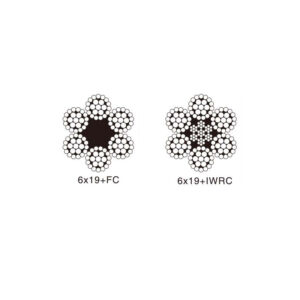

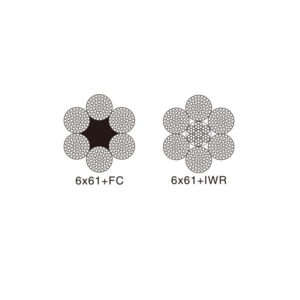

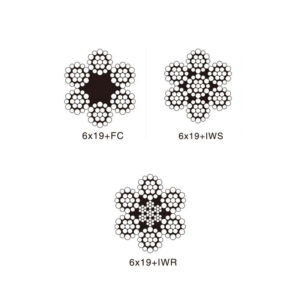

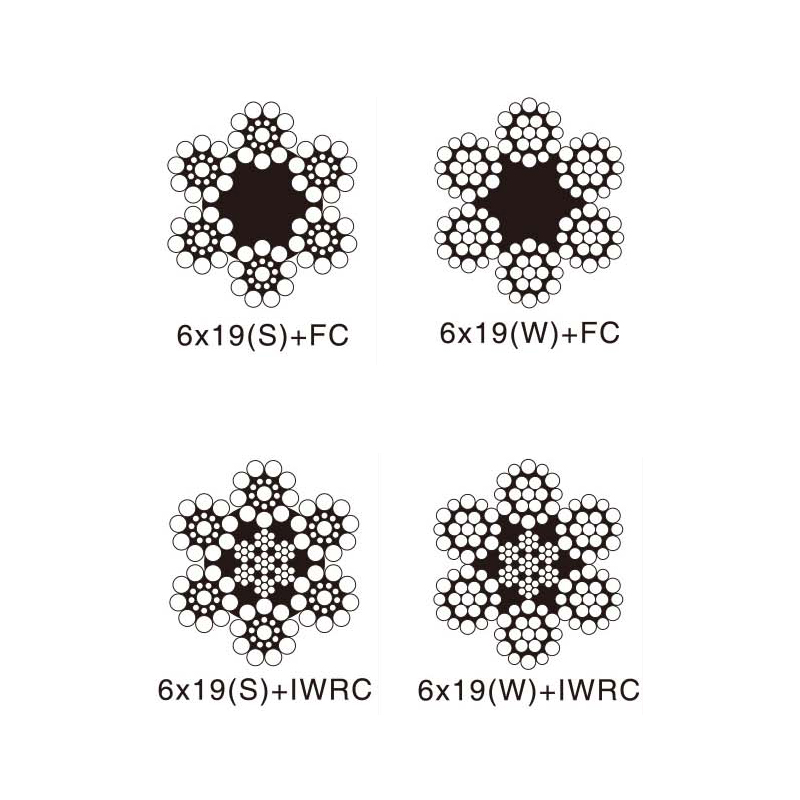

DIN 3058 6*19 Line Contacted Steel Wire Rope is engineered for demanding industrial applications where strength and flexibility are essential. This wire rope is constructed with six strands, each containing 19 wires, creating a robust and flexible structure that excels in handling high-tension loads. The line-contact construction enhances the rope’s durability, ensuring it maintains its integrity under heavy use.

Available in both ungalvanized and galvanized finishes, this wire rope caters to a range of environmental conditions. The ungalvanized variant is ideal for indoor applications where corrosion is not a concern, while the galvanized version offers superior corrosion resistance, making it suitable for outdoor or marine environments.

The DIN 3058 specification ensures that this wire rope meets rigorous quality and performance standards, making it a reliable choice for industries such as construction, shipping, mining, and more. Its versatility and strength make it suitable for a wide range of uses, including lifting, rigging, and securing loads.

• Construction: 6 strands with 19 wires per strand, providing excellent flexibility and strength.

• Finish Options: Available in both ungalvanized for indoor use and galvanized for enhanced corrosion resistance in harsh environments.

• Durability: Line-contact construction enhances the rope’s longevity, especially under high-tension conditions.

• Applications: Ideal for lifting, rigging, and load securing in industries such as construction, mining, and marine.