When it comes to selecting the right steel wire rope for mining applications, it’s all about safety and efficiency. The right rope can make a huge difference in how well your operation runs, and with so many options out there, it can be tough to know which one is best for you.

To choose the right steel wire rope for mining applications, you need to know how it’s made, how much it can hold, and how strong it is. The most important things to consider are tensile strength, abrasion resistance, and fatigue resistance. These factors will help you make the right decision and keep your mining operation safe and efficient.

Knowing these things will help you make the right choice and keep your mining operation safe and efficient.

How do I choose a steel wire rope?

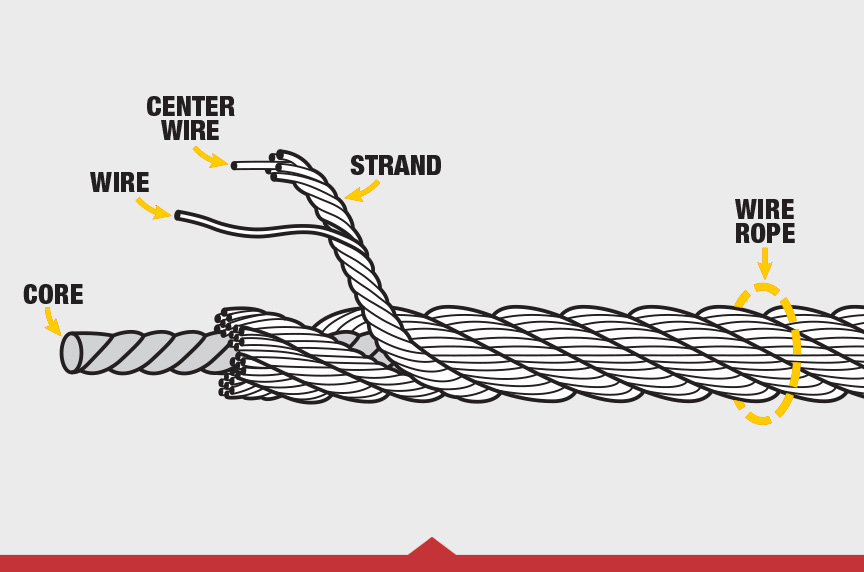

To select the right steel wire rope, you need to know how it’s made, how much it can hold, and how strong it is. Steel wire ropes are made up of a bunch of strands, which are made up of a bunch of wires. The way the wires are arranged and how many there are determines how strong and flexible the rope is. If you’re using it in a mine, you need to pick a rope that can handle the tough conditions you’ll find there, like heavy loads, rough handling, and bad environments.

Before you buy anything, think about what you need the rope to do. You need to know how much weight the rope will have to hold and what kind of machines you’ll be using it with. Make sure the rope you get can do what you need it to do.

What are the four characteristics to consider when selecting a wire rope?

1. Strength: The rope must be strong enough to handle the biggest loads you’ll ever put on it. You want a rope that has a higher strength rating than the maximum load you’ll ever put on it so you don’t have to worry about it breaking.

2. Fatigue Resistance: Mining operations involve a lot of loading and unloading. You want a rope that can handle these cycles without breaking.

3. Abrasive Wear Resistance: The mining environment is tough on equipment. There’s a lot of debris and rough surfaces that can wear down your equipment. You want a rope that can handle this environment.

4. Overall Durability: Consider the rope’s overall durability, including its resistance to corrosion and other environmental factors. You want a rope that’s going to last.

What are the factors considered while selecting steel wire ropes?

- Tensile Strength: This is the maximum amount of weight the rope can hold before it breaks. Always choose a rope with a higher tensile strength than the weight you plan to put on it.

- Abrasion Resistance: Think about the materials and coatings used on the rope because they affect how well it stands up to rubbing.

- Resistance to Bending Fatigue: As you wind and unwind a rope, it bends. A rope that resists bending fatigue will last longer when you use it over and over.

- Environmental Considerations: If you use a rope in a place that’s wet, corrosive, or has extreme temperatures, you need a rope made of special materials and coatings.

Look at these things carefully to pick a rope that does what you need it to do and keeps you safe.

What is the rule of thumb for wire rope?

A good rule of thumb to determine the safe working load (SWL) of a wire rope is to multiply the square of the diameter of the rope by eight. SWL = (D²) × 8. This rule will give you a quick estimate of the load capacity of the rope and help you select the right rope for the job. Make sure you inspect the rope regularly for wear. Wear will affect the load capacity and the safety of the rope.

Why is professional consultation important?

With so many different types of steel wire ropes available, it’s a good idea to consult with professionals or suppliers who can help you make the right choice. They can recommend the best type of rope for your specific needs and also keep you up to date on the latest technology and developments in wire rope manufacturing. In addition, a good supplier will provide support after the sale and training to make sure you get the most out of your investment.

Summary

In conclusion, choosing the right steel wire rope is important for safety and productivity in mining. By understanding key factors like tensile strength, fatigue resistance, and environmental durability, you can make informed buying decisions that meet your company’s needs. Also, talking to industry experts can help you learn more and make sure you’re buying the right products for your applications.

By paying attention to these important factors, you can establish a reliable supply chain and improve your operation’s efficiency, making sure your mining goes smoothly and safely.