When it comes to industries like mining, marine, logistics, construction, and manufacturing, selecting the right shackles is critical to ensure safe and efficient lifting operations. Choosing the wrong type or quality of shackle can lead to operational failures and severe accidents. This guide is going to help B2B procurement managers make informed decisions by highlighting key factors to consider when selecting high-quality shackles.

To choose high-quality shackles, you need to consider the material (stainless steel for corrosive environments or alloy steel for heavy-duty use), the working load limit (WLL) that exceeds the intended load, and compliance with standards like ISO and CE. You also want to look for suppliers who offer certified, tested shackles so you don’t have accidents because you bought some cheap crap.

Let’s dig into each of these factors to understand how they impact the safety and efficiency of your lifting operations.

What Materials Are Best for Shackles in Different Environments?

When it comes to choosing shackles for lifting, the material is going to play a big role in determining how durable and safe they are. The two most common materials you’re going to see are stainless steel and alloy steel.

- Stainless Steel: This is the stuff you want to use if you’re in a corrosive environment, like the marine or chemical industries. It’s going to resist rust and corrosion really well, so it’s going to last a lot longer in those harsh conditions.

- Alloy Steel: This is the stuff you want to use if you’re doing heavy-duty stuff, like mining or construction. It’s going to be really strong and durable, so it’s going to be able to handle higher load capacities.

Choosing the right material is going to make sure that your shackles can handle the specific environmental conditions you’re going to be in, which is going to reduce the risk of wear and tear that could compromise safety.

How to Determine the Right Size and Type of Shackle for Your Needs?

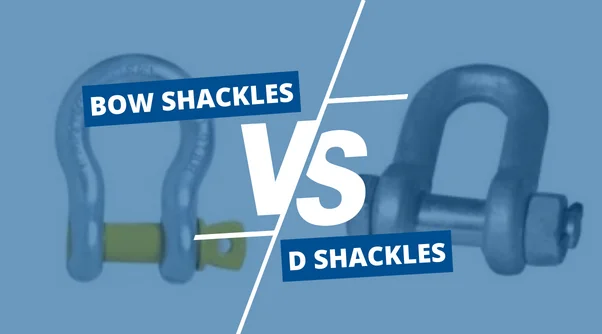

Choosing the right size and type of shackle is critical to safely handle your loads. There are a couple different types of shackles you’re going to see, including bow shackles and D shackles:

- Bow Shackles: These are great when you’re going to have loads that are going to shift around on you. They’re commonly used in rigging and lifting applications where the load might move. They give you some flexibility in connecting multiple slings or chains.

- D Shackles: These are designed for loads that are going to be in-line, where the pulling direction is straight. They’re great for static or linear lifting applications.

The size of the shackle needs to match the diameter of the chain or rope you’re using to make sure you have a secure connection. Always check the manufacturer’s specs to get the right sizing information.

What is the Working Load Limit (WLL) and Why Does It Matter?

The Working Load Limit (WLL) is the maximum weight that a shackle can safely handle under normal operating conditions. It’s really important to choose a shackle that has a WLL that’s going to comfortably exceed the weight of the load you’re going to put on it so you don’t have accidents.

Never exceed the WLL of a shackle. If you do, you can cause deformation or failure, which can lead to some really bad stuff happening. Always refer to the manufacturer’s guidelines for WLL information.

Why is Certification and Compliance Essential for Shackles?

Certification and compliance with international standards, like ISO and CE, are really important to make sure your shackles are safe and reliable. Certified shackles have been tested to meet strict safety standards, so you know they can handle the demands of industrial lifting operations.

Look for shackles that have these certifications to make sure they meet the quality standards you need. Stay away from shackles that don’t have these certifications because they might not be as safe or perform as well.

How to Identify High-Quality Shackle Suppliers?

Choosing a reliable supplier is just as important as choosing the right shackle. Here are some tips to help you find good suppliers:

- Check Certifications: Make sure the supplier you’re looking at offers products that meet international standards like ISO and CE.

- Review Customer Feedback: Look for testimonials and reviews from other people in your industry to see what kind of reputation the supplier has.

- Verify Compliance: Make sure the supplier you’re looking at complies with local and international safety regulations.

- Assess Product Range and Availability: A good supplier is going to have a variety of shackles for different applications and environments.

Working with a good supplier is going to help you reduce your risks and make your operations safer.

Which Shackles Are Not Suitable for Overhead Lifting?

Round pin shackles are not recommended for overhead lifting applications because they can’t handle a lot of dynamic loads. They’re typically used for non-critical, static applications where the load isn’t going to move or shift. When you’re doing overhead lifting, always use shackles that are designed specifically for that purpose, like bolt-type or safety pin shackles.

What Are the Industry Trends in the Demand for High-Quality Lifting Equipment?

The global market is seeing a growing demand for high-quality lifting equipment. Factors like an increased focus on workplace safety, stricter regulations, and a greater awareness of the risks associated with using crappy products are driving this trend. Businesses are now prioritizing quality and safety certifications when they’re picking out lifting equipment so they can reduce their risks and improve their operational efficiency.

How Do Substandard Shackles Contribute to Workplace Accidents?

Using crappy shackles can lead to some really bad accidents at work. Studies have shown that faulty lifting equipment is a big cause of injuries and deaths at work. For example, in a study done by the Occupational Safety and Health Administration (OSHA), they found that a big percentage of lifting accidents were because of shackles that hadn’t been tested right or weren’t certified. That’s why it’s so important to choose shackles that are certified and good quality so you don’t have those risks.

Summary:

Choosing the right shackles is really important to make sure your lifting operations are safe and efficient. By focusing on materials, WLL, certification, and working with good suppliers, you can reduce your risks and make your operations better. Always choose shackles that meet or exceed industry standards so you don’t have accidents and your operations go smoothly.