Quick Key Takeaways: What You Need to Know About Electric Chain Hoists

| Key Aspect | Critical Insights | Performance Impact |

|---|---|---|

| Load Capacity | Determines maximum safe lifting weight | Prevents workplace accidents and equipment damage |

| Lift Height | Defines vertical movement range | Ensures operational flexibility |

| Safety Standards | Must comply with industry regulations | Guarantees workplace protection |

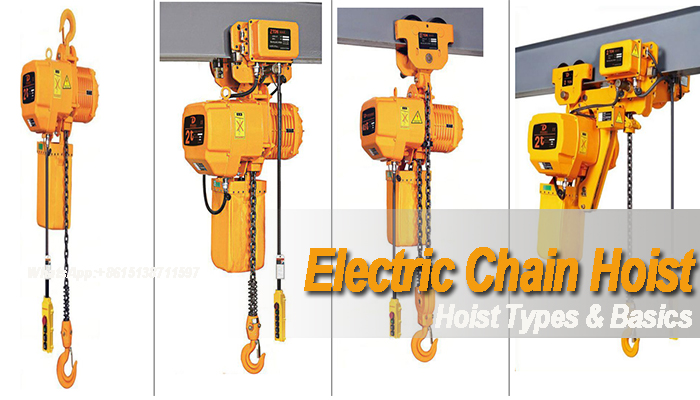

What Exactly is an Electric Chain Hoist?

An electric chain hoist is a powerful mechanical device designed to lift and move heavy loads vertically using an electric motor and a sturdy chain. Unlike manual hoists, these advanced machines provide efficient, safe, and precise lifting capabilities across various industrial applications.

Understanding Your Project Requirements

Before selecting an electric chain hoist, consider these crucial factors:

- Load Weight: Precisely calculate the maximum weight you’ll be lifting

- Lift Height: Measure the vertical distance your materials need to travel

- Operational Environment: Assess temperature, humidity, and potential exposure to chemicals

Types of Electric Chain Hoists for Different Needs

Electric chain hoists aren’t one-size-fits-all. Here are the primary types:

- Standard Electric Chain Hoists: Perfect for general lifting tasks in warehouses and manufacturing

- Variable Speed Hoists: Ideal for precision lifting requiring controlled movement

- Double Chain Hoists: Designed for balanced lifting of bulky or awkward loads

Critical Customization Considerations

When customizing your electric chain hoist, focus on these key features:

- Lifting Capacity: Match the hoist’s capacity exactly to your requirements

- Speed Control: Choose models with adjustable lifting and lowering speeds

- Power Supply Compatibility: Ensure electrical specifications match your facility’s infrastructure

Safety Standards: Non-Negotiable Protection

“Safety isn’t expensive, it’s priceless.” – Unknown

Electric chain hoists must comply with rigorous safety standards, including:

- OSHA workplace safety regulations

- ASME B30.16 safety standards for overhead hoists

- International electrical safety certifications

Cost and Maintenance Insights

While initial investment matters, consider long-term value:

- Initial Cost: Range from $500 to $10,000 depending on specifications

- Annual Maintenance: Typically 5-10% of purchase price

- Lifespan: Well-maintained hoists can last 10-15 years

Industry-Specific Applications

Different sectors leverage electric chain hoists uniquely:

- Manufacturing: Assembly line material handling

- Construction: Vertical transportation of heavy equipment

- Warehousing: Efficient inventory management

Future Trends in Electric Chain Hoist Technology

Emerging innovations include:

- IoT-enabled monitoring systems

- Enhanced energy efficiency

- Predictive maintenance capabilities

Frequently Asked Questions

How do I choose the right electric chain hoist?

Consider load weight, lift height, environment, and specific industry requirements. Always consult with rigging experts like IVITAL for personalized guidance.