Standard jacks didn’t fit our pallets—and we paid for it in delays and equipment strain.

Customized hand pallet trucks solve unique handling problems by adapting fork size, wheel type, and load specs to match your workflow. Tailor-made solutions reduce damage, boost safety, and improve speed.

Let’s look at when customization matters most—and how brands like IVITAL make it easy.

[Table of contents]

- What are the benefits of a custom pallet jack?

- How can you customize a hand pallet truck?

- When should you use a tailor-made pallet jack?

- Are custom pallet jacks expensive?

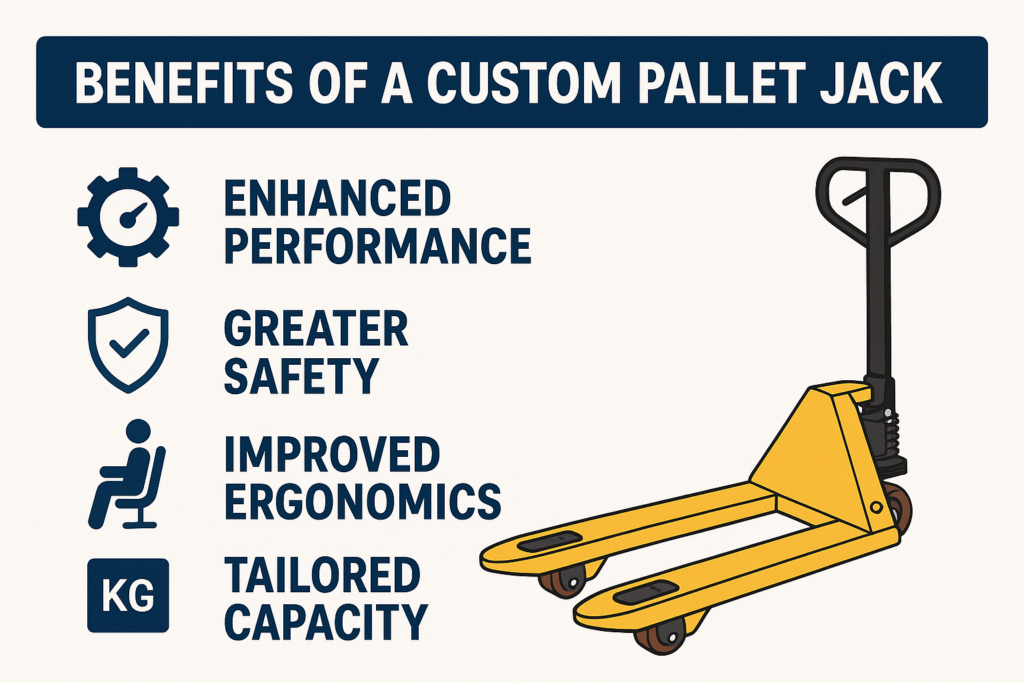

What are the benefits of a custom pallet jack?

One size doesn’t fit all—especially in manufacturing.

Custom jacks match your actual handling needs, reducing load shifting, floor damage, and worker fatigue.

Dive Deeper

| Standard Issue | Custom Solution |

|---|---|

| Forks too short | Extended fork lengths |

| Turns too wide | Narrow body and 4-way entry |

| Load damage | Wheel material matched to load type |

We switched to IVITAL’s custom pallet trucks after realizing our 1300mm crates hung over the forks. Their team built a 1400mm model with reinforced steel and better turning radius.

How can you customize a hand pallet truck?

More than just paint—custom means functional changes.

Fork size, frame width, wheel material, load rating, and handle ergonomics can all be adjusted to spec.

Dive Deeper

With IVITAL’s help, we specified:

- Fork length: 1450mm (instead of standard 1150mm)

- Width over forks: Adjusted to match our custom wood pallets

- Load rating: Upgraded to 3000kg for metal bins

- PU wheels: For quieter movement across epoxy-coated floors

- Ergonomic handle: Bent forward for reduced wrist strain

They even added our logo and asset barcode on the frame—great for inventory control.

When should you use a tailor-made pallet jack?

Not every industry can use off-the-shelf tools.

Custom trucks are ideal for tight aisles, delicate materials, oversized loads, or specific compliance needs.

Perfect use cases:

- Pharmaceuticals: Stainless steel, PU wheels, low-noise lift

- Food logistics: Galvanized frame, water-resistant seals

- Aerospace: Extra-long forks for fuselage parts or crates

- Retail warehouses: Narrow jacks to move stock between tight shelving

IVITAL builds ISO 3691-5 and CE-compliant jacks and even supports engineer-to-engineer file sharing for industrial buyers who want full control.

Are custom pallet jacks expensive?

Custom sounds costly—but what about the cost of downtime?

Custom jacks cost more upfront but pay off in fewer breakdowns, less manual effort, and better long-term fit.

Dive Deeper

| Type | Typical Price Range | Payoff |

|---|---|---|

| Standard Manual Jack | $250–$400 | Immediate use, low fit flexibility |

| Custom-Built Jack | $500–$850 | Matched fit, safer operations, longer lifespan |

IVITAL offers volume pricing and low MOQ for custom models, and includes engineering support for all custom orders.

They’re not just building jacks—they’re solving handling problems for specialized operations.

Conclusion

Yes—custom pallet trucks fix real-world problems. The right design turns wasted time into smooth handling.