I’ve dealt with jammed wheels and stuck hydraulics—usually at the worst possible time.

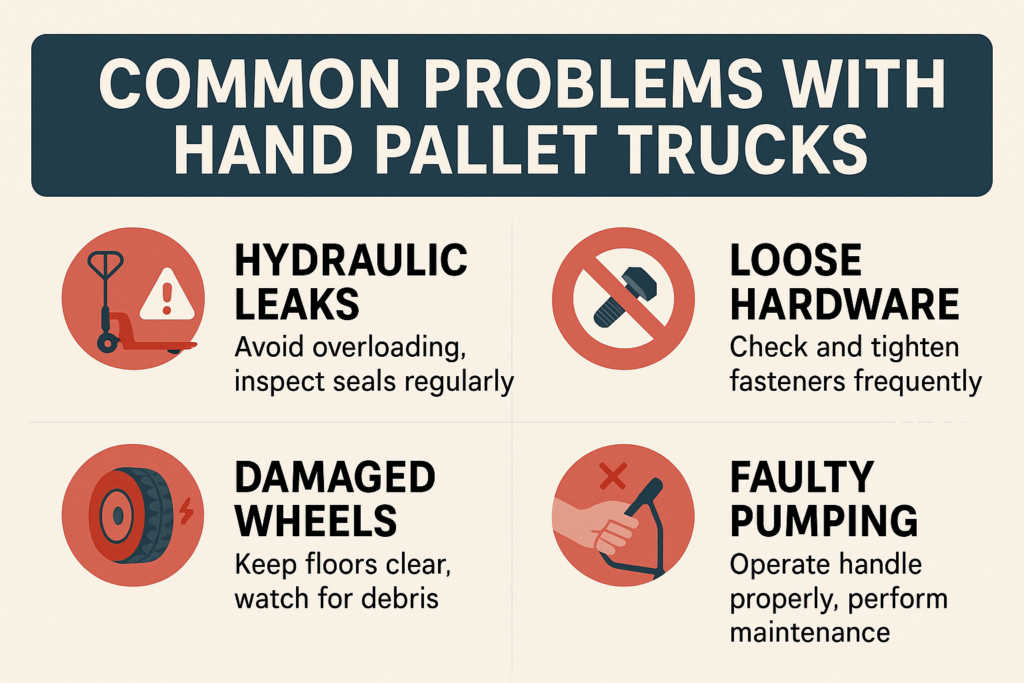

Common pallet jack problems include oil leaks, poor lifting, and worn wheels. Monthly maintenance, quick inspections, and using durable models like those from IVITAL can prevent costly downtime.

Let me walk you through the issues I’ve seen most—and how to fix or avoid them fast.

[Table of contents]

- How to maintain a pallet truck?

- What are the disadvantages of hand pallet trucks?

- What are the OSHA rules for manual pallet jacks?

- What should you never do when pulling a hand pallet truck?

How to maintain a pallet truck?

Maintenance is easier than repairs—if you do it right.

Lubricate monthly, inspect forks and seals, and clean moving parts after washdowns to prevent common breakdowns.

Dive Deeper

Here’s my monthly checklist for keeping pallet jacks running smooth:

| Maintenance Task | Frequency | What to Check |

|---|---|---|

| Grease wheels/axles | Monthly | Smooth rolling and turns |

| Check hydraulic fluid | Quarterly | Proper lift/lower response |

| Inspect forks/frame | Weekly | Cracks, bends, or dents |

IVITAL’s hand pallet trucks come with grease ports, sealed bearings, and reinforced frames, which make preventative care quick and easy.

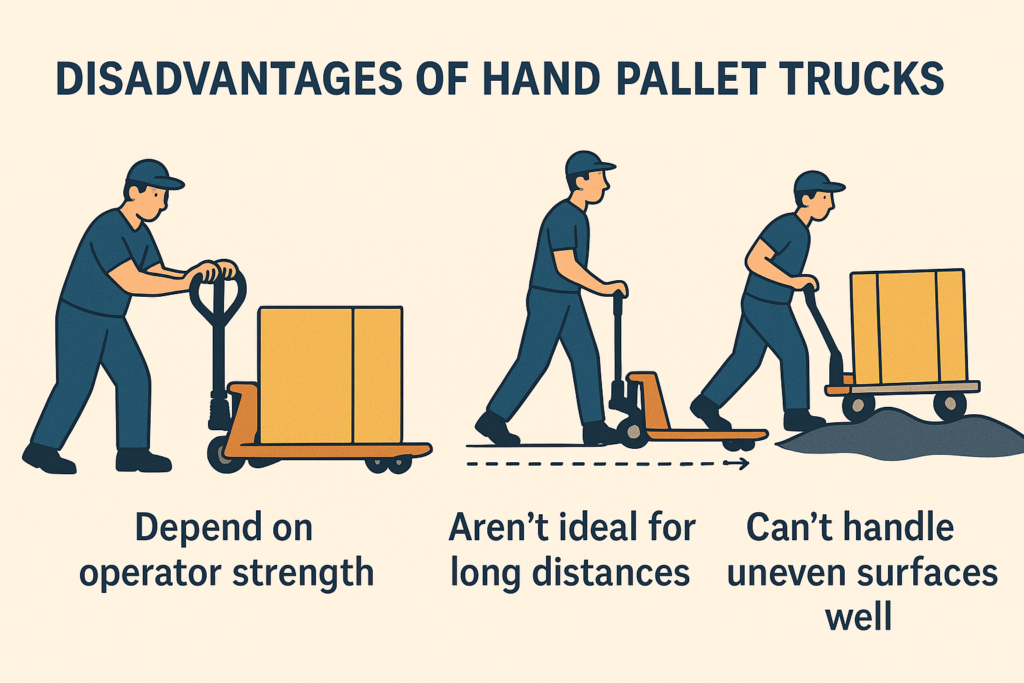

What are the disadvantages of hand pallet trucks?

Manual tools save money—but come with limits.

They depend on operator strength, aren’t ideal for long distances, and can’t handle uneven surfaces well.

Dive Deeper

If you’re using manual jacks on older floors, you’ll notice:

- Operators fatigue faster with heavy loads

- PU or nylon wheels wear quickly on rough concrete

- Tight turns become hard when loads are oversized

We upgraded to IVITAL ergonomic models with low-friction steering systems and noticed better control on ramps and smoother turns in confined zones.

What are the OSHA rules for manual pallet jacks?

Even “manual” doesn’t mean unregulated.

OSHA doesn’t require certification, but training in safe operation and inspections is strongly advised.

Dive Deeper

Here’s what we follow:

- Never overload beyond rated capacity (usually 2500–3000 kg)

- Train staff to push, not pull, when possible

- Store the jack with the handle up to prevent accidents

IVITAL helps with compliance by providing:

- Visible capacity labels

- Illustrated safety guides

- Optional inspection tags attached to the jack’s handle

What should you never do when pulling a hand pallet truck?

This is where injuries usually happen—not on the clock, but in a rush.

Never run, take sharp corners, or operate loaded trucks on slopes without braking control.

Dive Deeper

Common unsafe practices I’ve corrected:

| Unsafe Action | Safer Alternative |

|---|---|

| Running with a load | Walk at controlled pace |

| Sharp corner turns | Stop, reposition if needed |

| Downhill pulling on slope | Keep load in front, use both hands |

IVITAL pallet trucks include wide-grip ergonomic handles that give better leverage and control during turns or while slowing on declines.

Conclusion

Most pallet jack issues start with neglect—stay ahead with routine checks and smart equipment choices.