Before I order any lifting gear, I ask one question: what’s the SWL?

Safe Working Load (SWL) is the maximum weight that rigging or lifting equipment can safely support under normal use.

I almost had a project shutdown once for overlooking SWL. Good thing I double-checked the specs.

[Table of contents]

- What’s the difference between SWL and WLL?

- How do you calculate Safe Working Load?

- Why is SWL important in rigging safety?

- What is the typical safety factor used in SWL?

- How do I use a Safe Working Load chart?

- What’s the lifting limit for shackles and slings?

- Conclusion

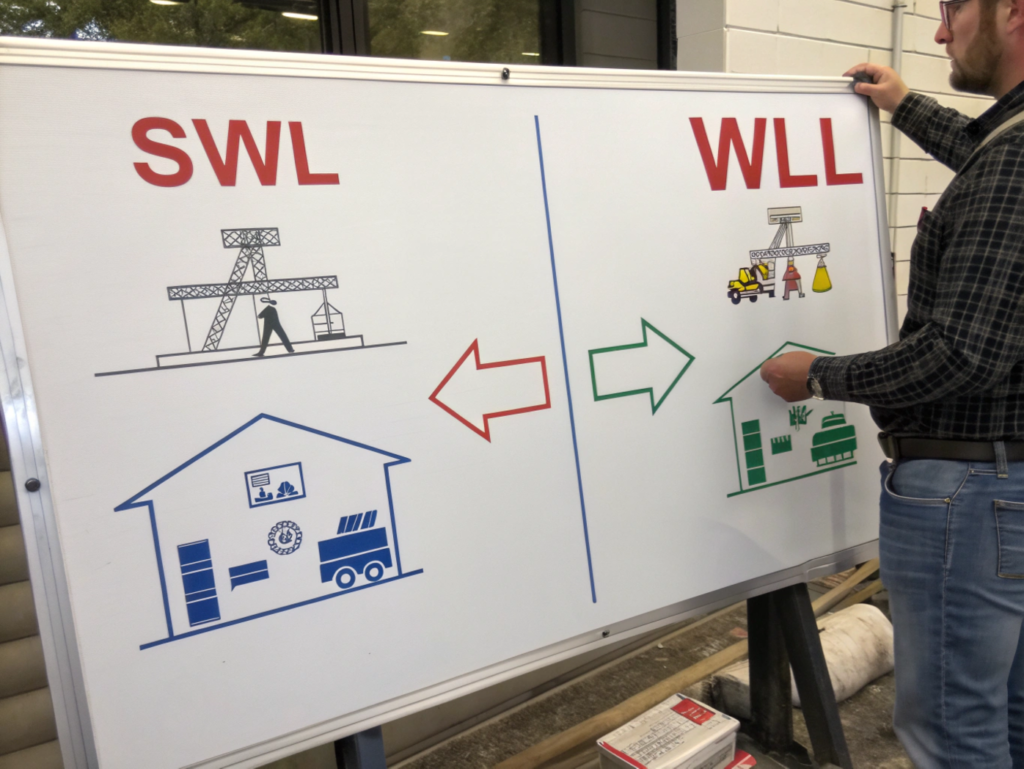

What’s the difference between SWL and WLL?

I used to mix these up a lot. I had to go back through manuals just to understand the difference.

SWL is an older term, while WLL (Working Load Limit) is now more widely used in industry standards.

Why are there two terms?

SWL was commonly used in the past, but WLL is now preferred by manufacturers and safety authorities. They both mean the same thing: the maximum load the equipment can handle safely.

The key difference is in who defines it:

- SWL is often calculated or certified by an engineer.

- WLL is provided by the manufacturer, based on lab testing and international standards.

| Term | Defined by | Used in |

|---|---|---|

| SWL | Engineer or inspector | Legacy manuals, site reports |

| WLL | Manufacturer | Modern spec sheets, labels |

How do you calculate Safe Working Load?

I always check how SWL is calculated before I buy anything.

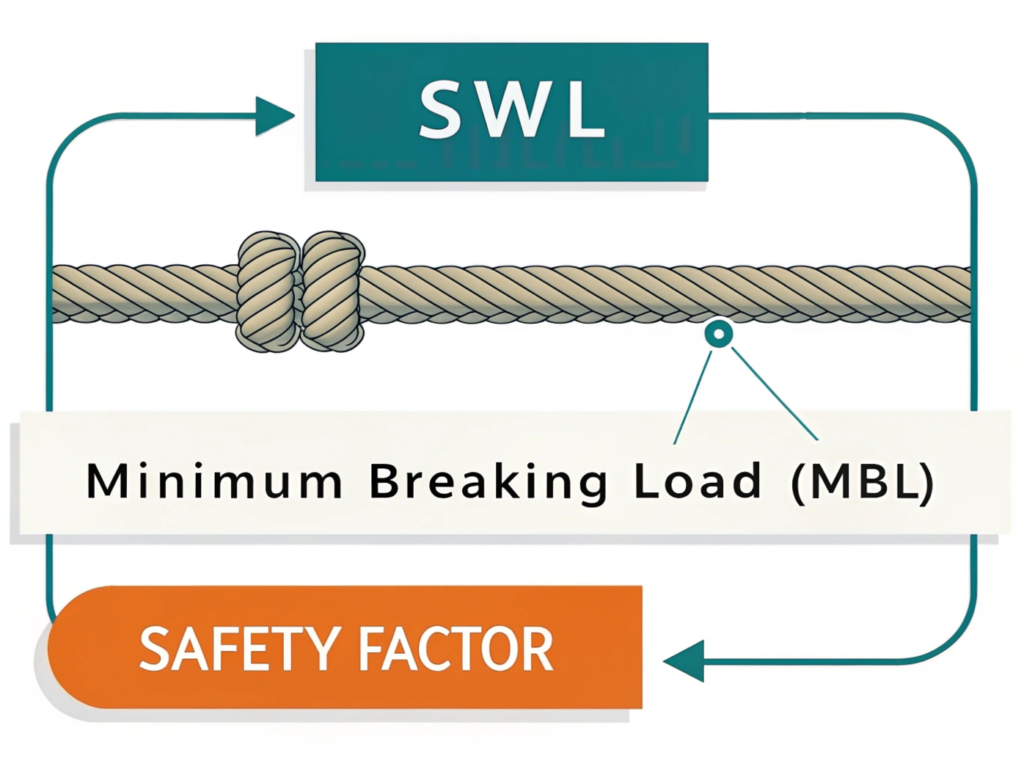

SWL = Minimum Breaking Load (MBL) ÷ Safety Factor, usually 5.

Let me show you with a real example

Let’s say I’m using a G80 chain sling. It has a Minimum Breaking Load (MBL) of 10 tons.

The standard safety factor is 5. That means:

SWL = 10 tons ÷ 5 = 2 tons

Even though that chain can handle up to 10 tons before snapping, I can only use it for 2 tons safely. That’s what SWL protects me from—pushing my luck.

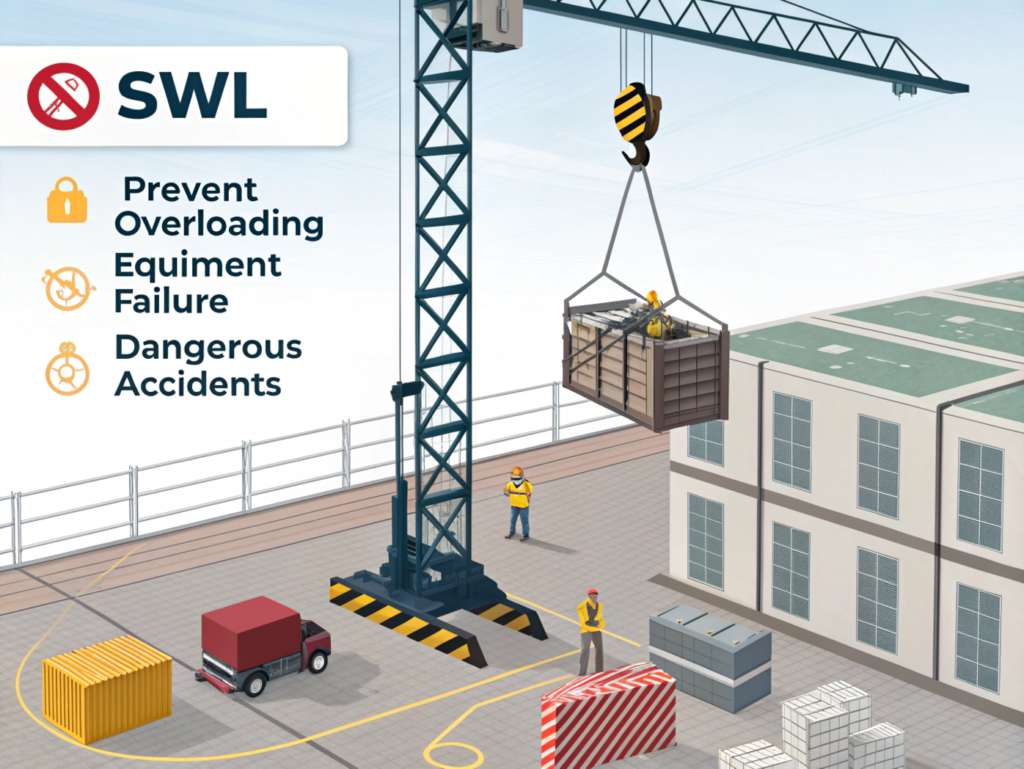

Why is SWL important in rigging safety?

Most lifting accidents I’ve seen come from ignoring the SWL.

SWL helps prevent overloading, equipment failure, and dangerous accidents during rigging operations.

I’ve been there — here’s what happened

Once, we swapped out a hook at the last minute on a site job. We didn’t check the SWL. Halfway through the lift, I felt something was off.

Turns out the hook had half the SWL of the original one.

We stopped in time, but if we hadn’t, it could have caused serious damage—or worse.

That’s when I started treating SWL as a non-negotiable step in every lift plan.

What is the typical safety factor used in SWL?

I get this question from clients all the time—what safety factor should they use?

The industry standard safety factor is 5:1, but it depends on the application.

It’s not always 5

Different rigging products require different safety margins. Here’s a quick reference table:

| Equipment Type | Safety Factor |

|---|---|

| General lifting slings | 5:1 |

| Hoist hooks | 4:1 or 5:1 |

| Personnel lifting systems | 10:1 |

| Custom-designed tools | Varies |

At IVITAL, we make sure every product is marked with its safety factor clearly. Especially for applications involving people or critical loads, a higher safety factor adds a huge layer of protection.

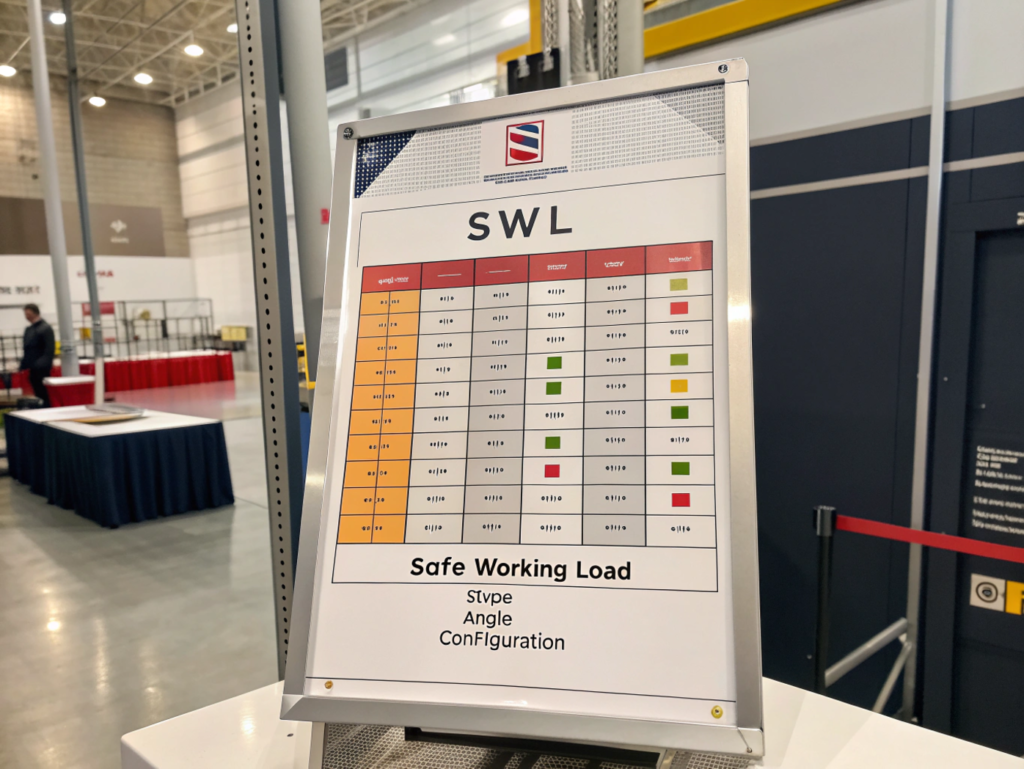

How do I use a Safe Working Load chart?

Opening paragraph for h2:

A lot of people ask me how to read those load limit charts that come with gear.

SWL charts list the maximum weight your gear can safely lift, based on type, angle, and configuration.

Dive Deeper: A real chart makes it clearer

If you’re using a chain sling, the load you can lift changes based on how you use it. For example, a straight vertical lift can carry more than a two-leg angled lift.

Here’s a sample from our IVITAL G80 chain sling chart:

| Chain Size (mm) | Single Vertical (tons) | 2-Leg 60° (tons) | 4-Leg 60° (tons) |

|---|---|---|---|

| 8 | 1.5 | 2.1 | 3.2 |

| 10 | 2.5 | 3.5 | 5.3 |

| 13 | 4.5 | 6.3 | 9.4 |

Always match your lift angle to the chart. If you guess or assume, you’re taking a serious risk.

What’s the lifting limit for shackles and slings?

Opening paragraph for h2:

People often overlook the smaller hardware—shackles, slings, links.

Every shackle and sling has a WLL or SWL clearly marked on the body or its label.

Dive Deeper: Here’s how we handle this at IVITAL

We engrave the WLL on all our shackles—3.25T, 4.75T, and so on.

For slings, we use both labels and color coding to indicate the SWL.

Here’s what I recommend to clients:

- Always save the original product specs from the supplier

- Inspect the hardware regularly for worn-out markings

- If using multiple slings together, always base the setup on the lowest SWL

Trust me—it’s the smallest parts that usually get missed, but they carry the biggest risk if they fail.

Conclusion

SWL isn’t optional—it’s the foundation of safe rigging.