In some industries, like machining, machine maintenance, engineering, construction, and many others, they use the same types of tools for different things, and over the years, the terms for those tools have become interchangeable. That’s the case with shackles and clevises, as they’re pretty much the same thing.

If you called something a clevis in the past few decades, someone would correct you and say, “No, that’s a shackle,” and vice versa. In this article, we’re going to talk about the similarities and the difference between shackles and clevises.

The Similarities Between Shackle and Clevis Fasteners

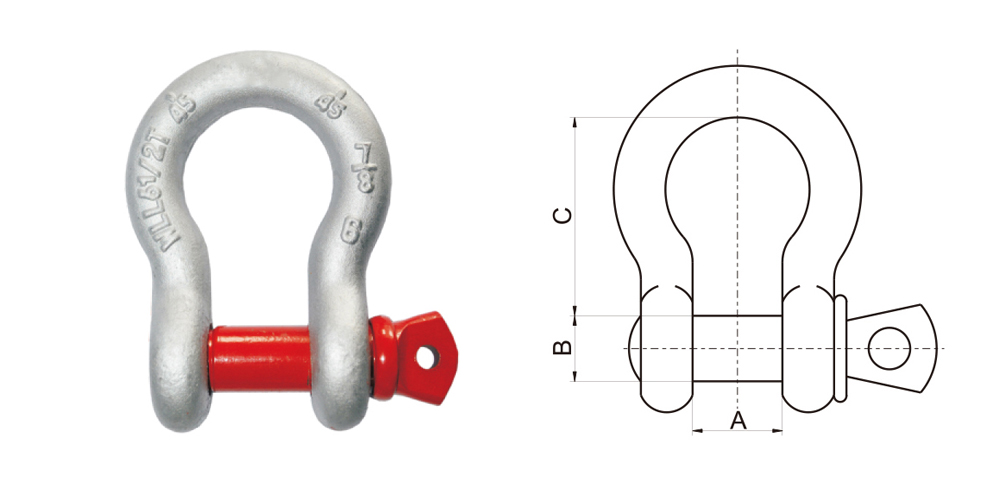

Shackles and clevises are U-shaped mechanical coupling devices that are usually closed by some type of fastener, whether a bolt or a threaded pin. In most cases, these U-shaped pieces are used to facilitate attaching a chain, a rope, or a wire rope for rigging purposes, hoisting, or towing applications.

Shackles and clevises are designed in varying levels of working load limit (WLL), with various types of pins, and in various styles, and contrary to popular belief, their size is specified by the diameter of the shackle or clevis body, and not by the diameter of the threaded bolt, or a clevis fastener.

However, their main difference is mostly in their working load limit and certain nuances in their design, which also dictate their overall application. Let’s look at those differences.

Understanding the Key Differences Between U-Shackles and U-Clevis Fasteners

The main difference is in the working load limit and their applications; clevises are mostly used in farming towing applications, with shackles typically used in construction, lifting, and rigging.

Clevises are most typically constructed to allow a reasonable amount of vertical movement and an appreciable amount of horizontal or lateral movement, mostly associated with towing applications in farming and sailboat rigging.

Additionally, these types of fasteners are typically closed with a non-threaded clevis pin for easier uncoupling of farming equipment in towing applications. However, it’s worth noting that they might be used in conjunction with a cotter pin that would prevent the clevis pin’s accidental removal due to vibrations.

On the other hand, shackles are mostly used in rigging and lifting, as they’re made of stronger materials, such as alloy or stainless steel. Additionally, they’re usually secured via a threaded pin or a threaded bolt, which makes them suitable for overhead lifting. There are two different types of shackles:

- Anchor Shackles — These are also called bow shackles. They have a big O-shaped loop that’s better for multi-point connection.

- Chain Shackles — These are more commonly called D-shackles. They look like a link in a chain and are therefore narrower than your typical anchor shackle. They move less when you rig them up because they’re designed to primarily take the load in-line.

Different Kinds of Pins

While clevises are generally secured with a non-threaded clevis pin and shackles are secured with a threaded bolt, you can use either kind of pin for either kind of connector in most cases. Here are three kinds of pins:

- Screw Type — You can quickly secure a shackle or a threaded clevis by twisting it tight.

- Pin Type — You can easily put these in and take them out to secure a shackle or a clevis, but they’re not used as much because they can fall out.

- Nut, Bolt, and Cotter Pin Type — This is the most secure way to secure a shackle or a clevis because the nut holds the bolt in place and the cotter pin keeps the nut from vibrating off. These are good for radial and torsional loads, but they’re harder to put in and take out, so they’re better for semi-permanent applications.

Summary

All shackles are open rings, but not all open rings are shackles. Open rings represent a wider range of load-bearing elements, including shackles – elements designed for rigging and lifting.

If you want to learn more about shackles and open rings, please visit IVITALRIGGING, a global supplier of lifting rigging.