G80 chains are known for being strong and reliable, which is why they’re so popular for heavy lifting and industrial applications. However, corrosion is one of the main things that can mess up your chains, especially if you’re using them in a harsh environment. So, how does the corrosion resistance of G80 chains affect how long they last? Let’s talk about it.

The corrosion resistance of G80 chains affects how long they last. If you’re using your chains in a place with high humidity, near the ocean, or around chemicals, they can rust and corrode. You can make your chains last longer by putting a protective coating on them, like galvanizing or black oxide treatment, to help keep them from rusting and corroding. Over time, corrosion weakens the metal and makes it break, so it’s important to make sure your chains are protected from rust and corrosion if you’re using them in a harsh environment.

What is the Safety Factor of G80 Chains?

G80 chains have a safety factor of 4:1. This means that the chain can hold four times the load it is rated for before it breaks. This safety factor is important because it ensures that the chain is strong enough to handle extreme loads. However, the chain can be weakened by corrosion, which can reduce its safety factor. If the chain is severely corroded, it will lose its ability to hold as much weight over time, which can lead to dangerous failures. Therefore, it is important to have corrosion resistance to maintain the safety rating of the chain.

How Long Will My Galvanized G80 Chain Last?

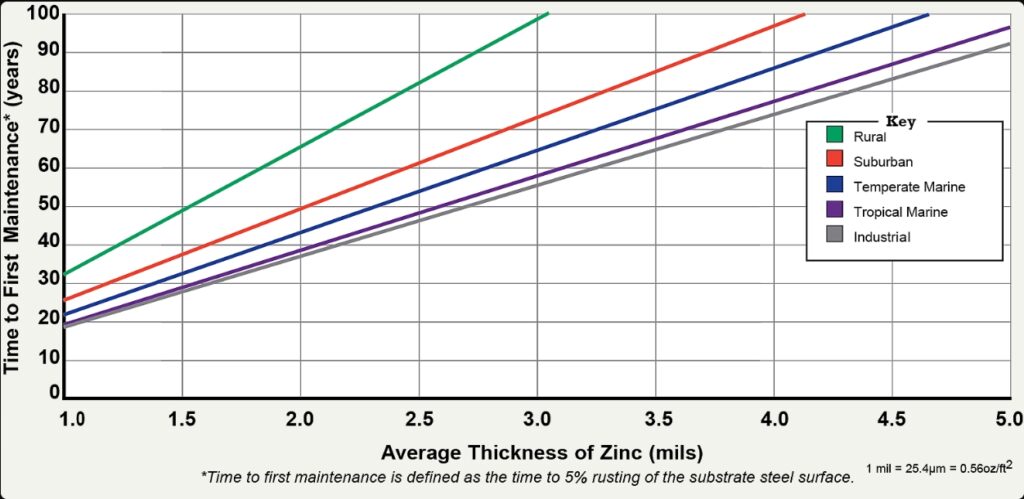

- Zinc Coating Thickness: The thicker the galvanized coating, the better the corrosion resistance. Chains with a coating thickness over 100 microns are considered protected, while those with 150 microns or more offer significantly enhanced corrosion protection.

- Corrosion Rate: Hot-dip galvanizing (HDG) protects steel by corroding at about 1/30th the rate of bare steel in similar environments. This means that G80 chains can last for decades in the right conditions, depending on the coating’s thickness and integrity.

- Environmental Impact: The effectiveness of galvanizing can vary greatly depending on environmental factors such as humidity, salt exposure, and temperature. In harsher environments, corrosion resistance may be reduced, requiring thicker coatings or more frequent inspections.

More information about hot-dip galvanized steels longevity can be found in the AGAs publication

Performance of Hot-Dip Galvanized Steel Products.

How Does Corrosion Affect G80 Chain Performance?

Corrosion is one of the biggest enemies of metal chains, especially when they are exposed to harsh environments like moisture, acid, or salt. Corrosion slowly eats away at the metal surface and weakens the internal structure, which reduces how much weight the chain can hold. Eventually, the corrosion makes the chain brittle, so it can’t hold as much weight as it should, and it can break when it shouldn’t.

How to Maintain the Longevity of G80 Chains?

To make your G80 chains last longer, you need to take care of them and use anti-corrosion stuff. Here’s what you need to do:

- Check Your Chains: Look at your chains to see if they’re rusty, worn out, or cracked. Even small cracks or rust spots can be signs that your chains are about to break.

- Lube and Rust Stuff: Use chain lube and anti-rust stuff on your chains all the time, especially if you’re in a wet or salty place.

- Store Your Chains Right: When you’re not using your chains, keep them in a dry, well-ventilated place where they won’t get wet.

Why You Should Lubricate Your Chain

- Less Friction and Wear: When you lubricate your chain, it cuts down on the friction between the moving parts. This means less wear and tear on your chain. In fact, a well-lubricated chain can last up to 100 times longer than a poorly lubricated chain.

- No Rust: When you lubricate your chain, it creates a barrier between the metal and the moisture and contaminants that cause rust. This is especially important if you ride in wet or dirty conditions.

- Better Performance: When you lubricate your chain, it moves more smoothly. This not only makes your bike ride better, but it also saves energy. When there’s less friction, you don’t have to work as hard to pedal your bike. Over time, this can save you a lot of energy and make your rides more enjoyable.

- Fewer Breaks: When you don’t lubricate your chain, it can wear out faster. This can lead to problems like the chain skipping or breaking. In fact, about 60% of chain failures are caused by a lack of lubrication. Regular lubrication can help prevent problems like premature wear of the pins and bushings, which can lead to expensive repairs and downtime.

- Keep the Lube Where It Belongs: When you lubricate your chain, you put a thin layer of lube on the pins and bushings. This keeps the metal parts from rubbing against each other. Over time, this lube can get pushed out of the way. That’s why it’s important to keep applying lube to your chain.

- Clean It Out: When you use a good-quality lube, it helps to flush out the dirt and debris that can get inside your chain. This helps your chain engage better with the sprockets and reduces wear.

Conclusion

If you want your G80 chains to last a long time, you need to make sure they don’t rust. You can do this by putting coatings on them and taking care of them. If you do this, your chains will last longer and work better in all kinds of places. If you have more questions about how to take care of your G80 chains, let us know and we’ll help you out.