Mining companies need to choose the right wire rope because their operations are tough. They often pick ungalvanized wire rope because it’s got special properties and works for lots of different things in mining. Why is it so great for mining? Let’s talk about what it is, what it does, and where you can use it.

Ungalvanized wire rope is made from steel without a zinc coating. That means it’s really strong and can take a lot of abuse. It’s great for mining because it can handle tough conditions and rough treatment. That’s why it’s a good choice for lifting, pulling, and other important mining jobs.

If you want to pick the right kind of wire rope for your mining job, you need to know what makes ungalvanized wire rope different from other types.

What Is Ungalvanized Steel Wire Rope?

Ungalvanized steel wire rope is made from high-carbon steel strands without a protective zinc coating. It is designed to be flexible, have a long fatigue life, and be strong. Ungalvanized ropes do not have a zinc coating like galvanized wire ropes. They are used where there is not much moisture and where there is a lot of abrasion.

In mining, ungalvanized wire ropes are used a lot for crane ropes, winch ropes, and hoist ropes. They work well in places where they have to carry heavy loads, go around sharp bends, and rub against rough surfaces, which is what happens in mining.

How Does Abrasion Resistance Affect Mining Operations?

Abrasion resistance is a big deal when it comes to how long wire ropes last in mining. Mining is tough on ropes. You’ve got rough terrain, sharp edges, and abrasive materials that can eat up a rope in no time. Ungalvanized wire ropes are great for these conditions because they’re naturally resistant to abrasion.

When you compare ungalvanized ropes to other types of ropes, ungalvanized steel is more resistant to wear and tear. That means they last longer and cost less to maintain. That’s why people use them when they’re pulling heavy loads across rough ground.

What Are the Specs and Structure of Ungal Wire Rope?

Ungal wire rope comes in a variety of configurations, each designed to meet specific requirements of mining operations. The most common specs include:

- Diameter: Ranges from small diameters (6mm) for lightweight applications to larger diameters (up to 60mm or more) for heavy-duty tasks.

- Strand Configuration: Typical constructions like 6×19, 6×37, or 8x36WS, which offer different balances of flexibility and strength.

- Core Type: Can be either fiber core (FC) or independent wire rope core (IWRC). IWRC cores provide higher strength and better resistance to crushing, making them more suitable for heavy-duty mining tasks.

These specs ensure the rope matches the specific load requirements and environmental conditions of mining operations.

Why Is Tensile Strength So Important for Mining Wire Ropes?

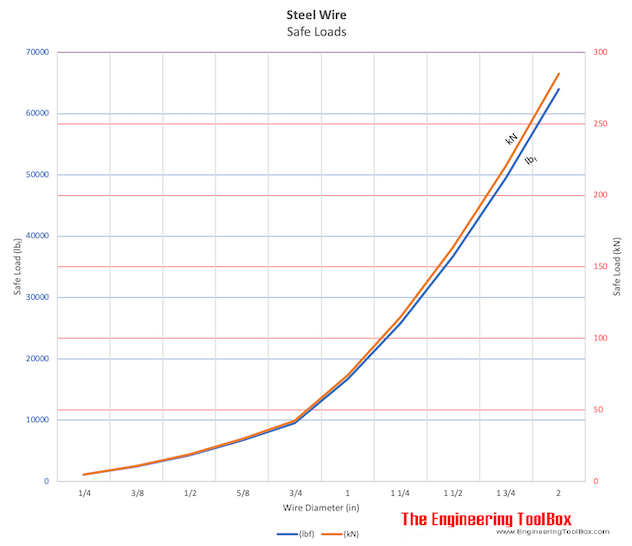

Tensile strength, or the maximum load a wire rope can bear before it breaks, is a big deal in mining. Ungalvanized wire ropes typically have a high tensile strength, which means they can handle heavy loads and won’t break under intense pressure.

For mining companies, it’s important to choose a wire rope with the right tensile strength because it keeps people safe and helps things run smoothly. The minimum breaking force of a wire rope should always be way above the maximum load it will ever see. This helps prevent accidents and keeps things moving.

Why Does Environmental Adaptability Matter in Mining?

Environmental adaptability is another thing to think about when you’re selecting wire rope for mining. Ungalvanized wire ropes are great when they’re not going to get wet or exposed to corrosive elements. But they’re more likely to rust and corrode than galvanized options.

In dry or abrasive environments, like a lot of mining sites, ungalvanized wire ropes work really well because they’re naturally resistant to abrasion and they’re strong. If you’re working in a wet or corrosive environment, you might need to do something else, like lubricate the rope, to make it last longer.

Ungalvanized vs. Galvanized Wire Rope: Which Is Better for Mining?

While both ungalvanized and galvanized wire ropes have their uses, ungalvanized wire ropes are generally preferred in mining due to their higher abrasion resistance and tensile strength. Galvanized wire ropes, with their protective zinc coating, are better suited for environments where corrosion resistance is critical, such as in marine or high-humidity applications.

For mining applications where abrasion and high tensile loads are common, ungalvanized wire ropes are typically the better choice. However, the specific requirements of each mining operation should always guide the selection process.

Summary

Ungalvanized wire ropes are a good choice for the mining industry because they are tough and can handle the rough conditions in mines. They are resistant to wear and tear and can handle the heavy loads that are common in mining. If you know what you’re doing, you can use ungalvanized wire ropes to get the most out of your mining operations and keep people safe.