Choosing the right size of chain release shackles is essential in the rigging industry, where safety and productivity are the name of the game. Chain release shackles are used to connect lifting slings, chains, or ropes on a wide variety of rigging applications and choosing the right size ensures that you will be able to accomplish this safely and efficiently.

Chain release shackles come in a bunch of different sizes, from dinky ones at one-half inch all the way up to monster ones at nine and a half inches. Each size has a maximum load that it is designed to accommodate and a range of applications in the rigging industry that it is ideal for. These sizes cover a wide range of tasks from lifting huge loads, to holding big loads in place, and various industrial applications.

Making sure that you get the correct shackle for what you’re doing is a major factor in safety and efficiency in any rigging operation.

What Are the Common Sizes for Chain Release Shackles?

Chain release shackles come in a range of sizes:

- 1/2 inch: This shackle size is perfect for lighter loads or small-scale, personal projects.

- 5/8 inch and 3/4 inch: These shackle sizes are excellent when a balance between strength, and ease of use is needed.

- 7/8 inch, 1 inch, and 1 1/8 inch shackles: These shackle sizes are often used for heavy lifts when strength and a higher capacity are needed.

- 1 1/4 inch and 9 1/2 inch shackles:These are the big ones. These shackle sizes are typically used in industrial, construction, or marine applications that are big and nasty.

Every size of shackle has a different combination of capacity and ease of use, so make sure that you select a shackle that meets the specific needs of what you are doing.

How to Choose the Right Size for Your Application?

When you are picking out your chain release shackle size, there are a couple of things that you ought to think about:

- Capacity: You need to know the capacity of the shackle that you are going to buy. You are going to have to make sure that the shackle that you get is rated for the capacity that you are going to use it for.

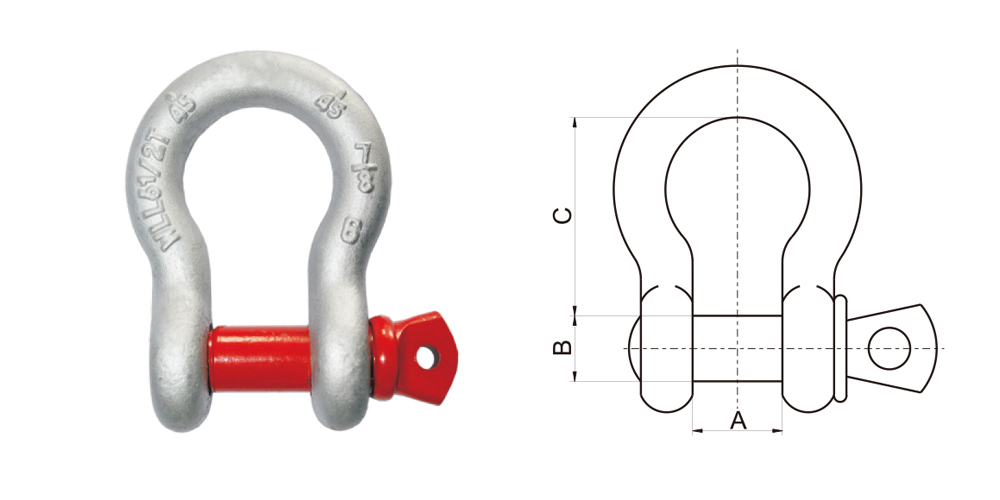

- Compatibility: This is the thing that has to fit together. You need to make sure that the shackle will fit in the holes in the loops or on the end of the slings that you get. Think about how you use it in order to get the right size.

- Environment: As you look at these different things, keep in mind the environment. There may be certain things about certain environments that dictate what size shackle you need to be using. Maybe there is something about the size of the hook or the strength that you need to have for a particular type of job.

For example, a 3/4 inch shackle is about the right size for a general purpose piece of equipment, you know, when you’re doing your everyday rigging chores. But if you’re going to lift a 100,000 pound steel coil off a barge, then you’re gonna need the size that’s an inch and a half.

What’s the Difference Between Measuring in Inches and Measuring in Metric?

Shackle sizes are mentioned in both the US and metric systems. Most of the work I do involves US measurements – in other words, inches, feet, and pounds, but I know there are shackles that get used in Europe, and some of the international stuff I do now that the shackles are sized up in millimeters. This means you will need to convert those millimeters to something that will work for the shackles that you’re doing. For example, you would have to convert 57 millimeters to get the correct dimension in inches to match to the US shackle sizes.

Applications of Different Sizes in Various Industries

- Maritime: The big one is the 1 1/2 inch shackle. This is the shackle that you’re going to see when they are anchoring a barge or a tugboat, or securing themselves to a pile driving rig. Anything that has any size or heft to it out on the water is going to be using this size shackle.

- Construction and Lifts: If you are lifting something that’s big and dirty – like moving steel coils out of the back of a truck – this family of shackles will be used: 7/8 inch, 1 inch, and 1 1/8 inch.

- General Purpose: Then we get down into the 1/2 inch and the 5/8 inch shackles. These are the general purpose shackles that you see used by the utilities, the guys doing the maintenance, or anybody needing to do any kind of general rigging.

Different sizes do different things depending on what you need them to do, so you can make sure each one is safe and works.

Safety Considerations When Selecting Shackle Sizes

- Check Them Out: Look at your shackles all the time to make sure they don’t have any wear, deformation, or damage.

- Don’t Overdo It: Don’t put more weight on a shackle than it’s rated for.

- Pick the Right Stuff: Make sure you use the right kind of shackle for where you’re using it, like galvanized shackles for the water or stainless steel shackles for places that are going to eat them up.

Summary

Picking the right size chain release shackle is important to make sure you’re safe and your rigging works right. By knowing what sizes are out there and what they’re for, you can make good choices to keep yourself safe and get your work done.