Picking the right D-ring shackle can be tough with all the types, materials, and standards out there. The right choice depends on your specific application, load requirements, and environmental conditions. This guide will help you understand the basics, identify the most suitable D-ring shackle for your needs, and follow essential safety precautions.

To choose the right D-ring shackle, consider the load capacity and match it with the shackle’s Safe Working Load (SWL). Make sure the shackle material is appropriate for the environmental conditions (e.g., stainless steel for marine environments, alloy steel for heavy-duty applications). Look for compliance with industry standards like CE, ISO, or ASME to ensure safety and quality.

Now let’s dig deeper into understanding the different types of D-ring shackles, their applications, and safety considerations.

What Are D-Ring Shackles and What Are They Used For?

D-ring shackles, also called Dee shackles, are U-shaped metal parts secured with a pin or bolt across the opening. They’re often used in lifting and rigging to connect different components like chains, ropes, and slings. The versatility and strength of D-ring shackles make them perfect for industries like construction, marine, mining, and logistics.

Types of D Ring Shackles: Which One is Right for You?

There are several types of D-ring shackles, each designed for specific applications:

- Bolt Type Shackles: These shackles have a bolt that screws into the body. They’re great for long-term installations where the shackle stays in place. They provide extra security against accidental removal.

- Screw Pin Shackles: These shackles have a pin that screws directly into the body. They’re easy to install and remove. They’re good for temporary applications where you need to put them together and take them apart quickly.

- Round Pin Shackles: These shackles are often used in towing and tie-down applications. They’re designed for light-duty jobs where you don’t have to worry about side-loading.

Knowing about these types will help you choose the right shackle for your specific application.

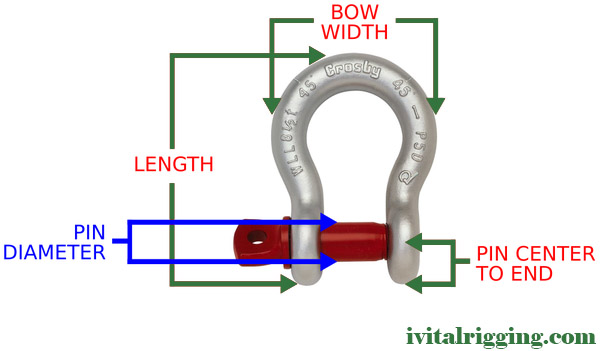

How to Measure D-Ring Shackles?

D-ring shackles are usually measured based on the diameter of the bow section, not the pin size. When you’re picking a shackle, always make sure the bow diameter matches what you need for your rigging setup. Also, look at the Maximum Working Load (MWL) to make sure the shackle can handle the load you’re putting on it.

Materials and Their Suitability: Which Material Should You Choose?

The material of a D-ring shackle determines how well it works in different environments:

- Alloy Steel: Alloy steel shackles are super strong. They’re great for heavy-duty applications like mining and construction.

- Stainless Steel: Stainless steel shackles don’t rust. They’re good for marine environments where saltwater can cause rust and damage.

- Galvanized Steel: Galvanized shackles are a good balance between cost and corrosion resistance. They’re versatile for general applications.

Choosing the right material will help your shackle last and perform well in your specific environment.

What Size Recovery Shackles Do I Need?

When you’re picking recovery shackles, measure the diameter of the hole in your bumper or tow point on your vehicle. Common sizes are 7/8-inch shackles with a 1.0-inch pin diameter and 3/4-inch shackles with a 7/8-inch pin diameter. It’s important to match the size of the shackle to the hole so you don’t damage anything and you can safely tow or recover.

Industry Standards and Certifications: What Should You Look For?

Certifications like CE, ISO, and ASME are important because they show that a shackle meets certain quality and safety standards. A CE mark means the shackle meets European safety standards. ISO certification means the shackle meets international quality standards. ASME certification means the shackle meets American engineering standards, which are often strict. Always look for these certifications when you’re picking shackles to make sure you’re getting a product that meets high safety and quality standards.

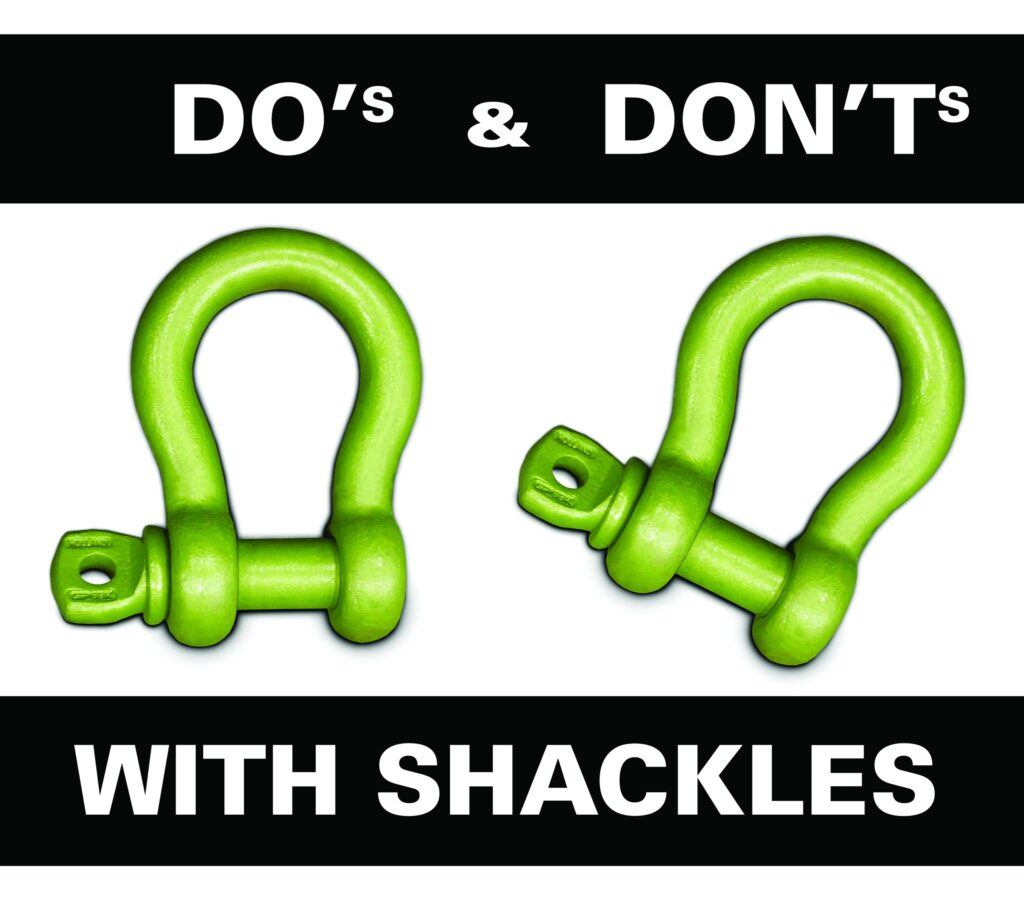

Safety Guidelines: Inspection, Maintenance, and Common Misuse

To make sure you’re using shackles safely, follow these guidelines:

- Regular Inspections: Look for wear, corrosion, or deformation before you use them.

- Proper Maintenance: Clean your shackles and put anti-corrosion stuff on them as needed.

- Avoid Common Misuse: Don’t go over the Safe Working Load (SWL) and don’t use a shackle that’s messed up.

By following these safety guidelines, you can avoid accidents and make your shackles last longer.

Supplier Selection Guide: How to Choose a Reliable Supplier?

When you’re picking a supplier, look at these things:

- Reputation: Check out the supplier’s history and what customers say about them.

- Certifications: Make sure the supplier’s products are certified to the standards you need.

- After-Sales Service: Find a supplier that offers good after-sales support, like warranties and technical help.

A good supplier will make sure the shackles you buy are good quality and safe.

Market Analysis and Future Trends in D Ring Shackles

The demand for D-ring shackles is expected to increase in industries like construction, marine, and mining because of more infrastructure development worldwide. Technological advancements will likely focus on making shackles out of stronger materials and adding smart features to help manage and monitor loads better.

Summary

Choosing the right D-ring shackle is important for keeping your operations safe and efficient. By knowing about the types, materials, certifications, and best uses, you can pick the right one for what you need. Always check the load capacity, inspect them regularly, and get them from a good supplier you trust.