Description

| Approx | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| NominalDiameter | Weight | ||||||||

| Construction | kg/100m | 1570N/mm² | 1770N/mm² | 1960N/mm² | |||||

| mm | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS | NF/SF | IWR/IWS | |

| 5 | 9.20/9.00 | 10.10 | 13.00 | 14.00 | 14.60 | 15.80 | 16.10 | 17.40 | |

| 6 | 13.30/13.00 | 14.60 | 18.70 | 20.10 | 21.00 | 22.70 | 23.20 | 25.10 | |

| 7 | 18.10/17.60 | 19.90 | 25.40 | 27.40 | 28.60 | 30.90 | 31.70 | 34.20 | |

| 6*19(S)+FC | 8 | 23.60/23.00 | 25.90 | 33.20 | 35.80 | 37.40 | 40.30 | 41.30 | 44.60 |

| 9 | 29.90/29.10 | 32.80 | 42.00 | 45.30 | 47.30 | 51.00 | 52.30 | 56.50 | |

| 10 | 36.90/36.00 | 40.50 | 51.80 | 55.90 | 58.40 | 63.00 | 64.60 | 69.70 | |

| 11 | 44.60/43.50 | 49.10 | 62.70 | 67.60 | 70.70 | 76.20 | 78.20 | 84.40 | |

| 12 | 53.10/51.80 | 58.40 | 74.60 | 80.50 | 84.10 | 90.70 | 93.10 | 100 | |

| 13 | 62.30/60.80 | 68.50 | 87.60 | 94.50 | 98.70 | 106 | 109 | 118 | |

| 14 | 72.20/70.50 | 79.50 | 102 | 110 | 114 | 124 | 126 | 136 | |

| 16 | 94.40/92.10 | 104 | 133 | 143 | 150 | 161 | 165 | 178 | |

| 18 | 119/117 | 131 | 168 | 181 | 189 | 204 | 209 | 226 | |

| 6*19(W)+FC | 20 | 147/144 | 162 | 207 | 224 | 234 | 252 | 258 | 279 |

| 22 | 178/174 | 196 | 251 | 271 | 283 | 305 | 313 | 337 | |

| 24 | 212/207 | 234 | 298 | 322 | 336 | 363 | 372 | 402 | |

| 26 | 249/243 | 274 | 350 | 378 | 395 | 426 | 437 | 471 | |

| 28 | 289/282 | 318 | 406 | 438 | 458 | 494 | 507 | 547 | |

| 30 | 332/324 | 365 | 466 | 503 | 526 | 567 | 582 | 627 | |

| 32 | 377/369 | 415 | 531 | 572 | 598 | 645 | 662 | 714 | |

| 6*19(S)+IWRC | 34 | 426/416 | 469 | 599 | 646 | 675 | 728 | 747 | 806 |

| 36 | 478/466 | 525 | 671 | 724 | 757 | 817 | 838 | 904 | |

| 38 | 532/520 | 585 | 748 | 807 | 843 | 910 | 933 | 1007 | |

| 40 | 590/576 | 649 | 829 | 894 | 935 | 1010 | 1034 | 1116 | |

| 42 | 650/635 | 715 | 914 | 986 | 1030 | 1110 | 1140 | 1230 | |

| 6*19(W)+IWRC | 44 | 714/697 | 785 | 1000 | 1080 | 1130 | 1220 | 1252 | 1350 |

| 46 | 780/761 | 858 | 1100 | 1180 | 1240 | 1330 | 1368 | 1476 | |

| 48 | 849/829 | 934 | 1190 | 1290 | 1350 | 1450 | 1490 | 1607 | |

| 50 | 922/900 | 1010 | 1300 | 1400 | 1460 | 1580 | 1617 | 1744 |

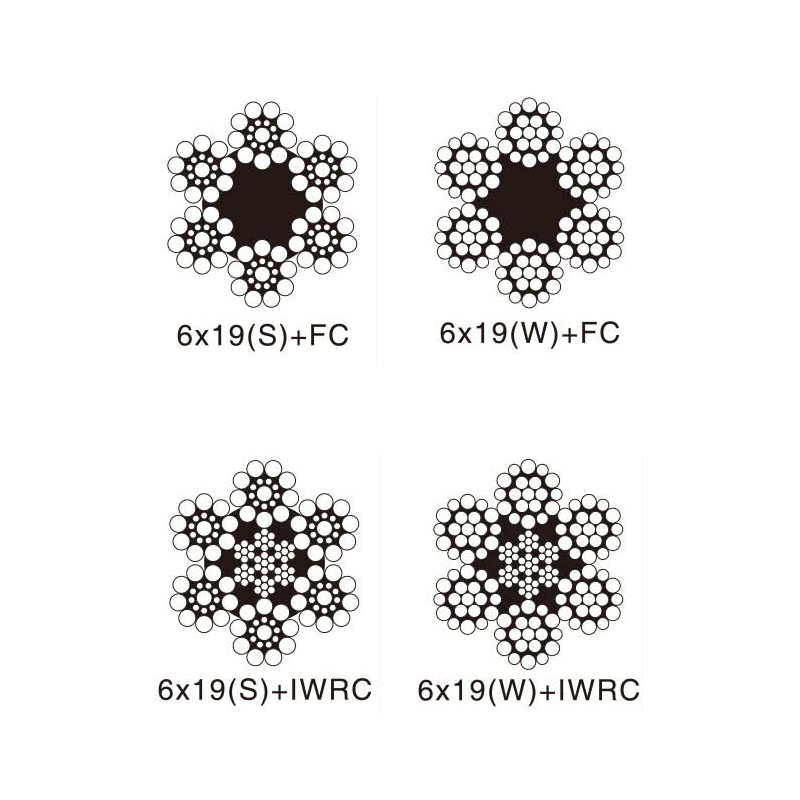

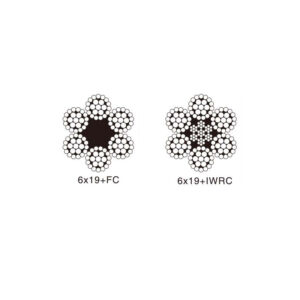

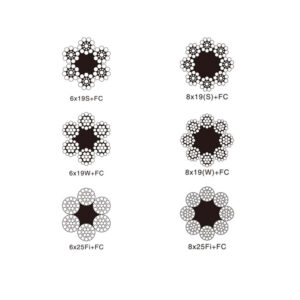

The DIN 3058-6×19 Steel Wire Rope is engineered to meet rigorous industrial standards, offering a perfect balance of strength, flexibility, and durability. Featuring a 6×19 construction, this steel wire rope comprises six strands, each containing 19 wires, which provides a superior combination of flexibility and resistance to abrasion and wear. This construction is particularly well-suited for demanding applications where a combination of strength and flexibility is required.

This wire rope is manufactured in accordance with the DIN 3058 standard, ensuring consistent quality and performance. It is an ideal choice for lifting, rigging, towing, and other heavy-duty operations. The rope is available in various diameters, catering to a wide range of load capacities and operational needs.

The 6×19 construction provides excellent fatigue resistance, making it suitable for applications where the rope is subject to continuous bending and flexing. This makes it a reliable option for cranes, hoists, winches, and other lifting equipment. The wire rope is also designed to withstand harsh environmental conditions, with a galvanized finish that offers enhanced protection against corrosion, ensuring a longer service life.

In summary, the DIN 3058 6×19 Steel Wire Rope is a versatile and durable solution for a wide range of industrial applications, providing the strength and reliability needed to perform under the most challenging conditions.

- Complies with DIN 3058 standards for quality and performance.

- 6×19 construction for optimal balance of flexibility and strength.

- Galvanized finish for superior corrosion resistance.

- Ideal for lifting, rigging, towing, and other heavy-duty applications.

If you have any questions about the DIN 3058 6×19 Steel Wire Rope, or need assistance in selecting the right wire rope for your application, please feel free to contact us.